Improving Warehouse Operations with Vehicle-Mounted Computers

MSC Home Terminal, the largest container terminal in the Port of Antwerp, is a 50/50 joint venture between PSA (Port of Singapore Authorities) and MSC (Mediterranean Shipping Company). MSC Home Terminal is the principal North European hub for MSC situated in the Delwaide Dock. The terminal has a total surface area of 1,628,000m2 with a total quay length of almost 3km. The annual TEU (twenty feet equivalent unit) capacity is around 4.3 million. MSC Home Terminal is equipped with state-of-the-art handling equipment and is controlled by high-performance IT applications. The working regime is therefore a continuous 24/7.

The Challenge

The container terminal operates in a complex dynamic environment, which is connected with a wireless network. MSC HT decided to replace the outdated narrow band system with a modern spread spectrum or WiFi 2.4 GHz and 5 GHz network. The narrow band system no longer sufficed, because it could only perform limited tasks such as moving containers from A to B, so-called “move” commands. That only requires a small bandwidth.

MSC HT wanted to evolve from text-based to graphical screens. Moreover, the technical department had clearly indicated that they wanted to set up proactive maintenance with which they could relay ‘alarms’ to the straddle carriers. After all a ‘strad’ needs servicing every 1,000 service hours.

Within MSC HT, Mr Hugo Borre, Technical Manager and Mr Eric Peeters, Manager Business Innovation, MSC Integration, PMO & ICT, were given the task of looking for a new supplier capable of fulfilling the package of requirements.

“The most important selection criterion was without doubt the robustness of the computers! To us there were no two ways about it, the devices just had to be extremely industrial,” Eric Peeters explains. “The computers in a straddle carrier are subjected to vibrations and shocks. They are used in all weathers too. In short, they needed to be as tough as our dockers.”

Because the technical department wanted to organise their proactive maintenance via pop-ups on the screen, the aspect of ‘readability’ was also quite important. “Now we can offer our drivers the choice of four different colour combinations for the screen,” Mr Peeters clarifies. “So they can decide the contrasts for themselves. There is absolutely no excuse for an unreadable screen these days.”

Everyone at MSC HT was involved in the selection procedure, right from management through to dockers and drivers.

The Solution

Out of the three candidates considered, Honeywell proved to be ‘best-in-class’. In opting for Honeywell, MSC HT already knew from beforehand that they would be getting hold of extremely dependable and robust computers. After all, for some time they have already been working on the quays and at the gates using handheld computers from Honeywell. They rely on these handheld devices throughout the year in all weather conditions, good or bad.

The users particularly tested the industrial character of the terminals, their ergonomics and screen readability. For their part, the maintenance department and the IT department were looking mainly at the technical side, because they needed a great many extra features for fully monitoring the straddle carriers using the new computers.

It should be no surprise that for their part the management looked at another aspect, the TCO or total cost of ownership. Decisive for them was the service contract that Honeywell was offering. Indeed, customers do know where they stand with this five-year contract.

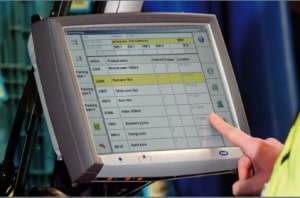

MSC HT will be installed around 120 VX9 computers by Honeywell in their straddle carriers. The VX9 does not have a hard disk but rather a flash disk and therefore does not play up under vibration or shock. The VX9 is implemented as a fat client so that it can communicate with an independent PLC and the TOS.

“I believe strongly in integration and conformity,” says Eric Peeters. “Integrating the various services at a port terminal is therefore paramount. Everyone and everything must work together seamlessly in order to arrive at a dynamic, well-oiled. If not, we would not be able to retain our world renowned, valued productivity.”

MSC Home Terminal cannot and must not ever come to a standstill. Every week, some 50,000 to 56,000 containers are loaded and unloaded from containerships. Every day too, about 1,400 containers are loaded and unloaded from lorries and on average 400 containers from train wagons. Likewise, many inland waterway vessels arrive daily to take containers to the hinterland.

In this distinctly multimodal world, we need to be sure that the right containers are put on the right transport. The dwell time for a container is just six days. Specifically, that means that a container is at the terminal for a maximum of six days. About 60% of containers do not even stay at the terminal but are loaded onto another means of transport straight away. The remaining 40% are given temporary pitches on the terminal.

In Antwerp, a deliberate choice was made for a wireless solution that is undeniably future-proof. The investment in the full monitoring of the straddle carriers both by IT – guiding the strads around the whole terminal – and by the technicians for the maintenance, shows a clear view towards the future. After all, moving forwards, this choice guarantees many possibilities! With an annual capacity of 4.3 million TEU, this is not insignificant and productivity can only profit from it too.

The Results

“The collaboration with Honeywell went very smoothly,” concludes Eric Peeters. “Furthermore, Honeywell listens to their customers and assimilate the information gathered in the design and development of new computers. Not only is that a pleasant thing to note, but also a reassuring one.”