Improving Location Tracking and Visibility with Data Collection Technology

Manual inventory and data collection processes are prone to errors which lead to data inaccuracies and erroneous reporting. In turn, this can cause customer dissatisfaction, supply chain delays, and higher operating costs. Location tracking solutions from RMS Omega are designed to eliminate errors, provide the most accurate and up-to-date information, and illuminate enterprise operations. Furthermore, locationing solutions can improve tracking with up to real-time data for:

- Physical inventory that’s counted, moved, shipped, sold, or consumed.

- Assets and tools including equipment, storage systems, furniture, IT, and shared electronic devices utilized by different team members.

- Parts, materials, and finished goods going through a manufacturing process.

- Personnel in dangerous and hazardous work environments.

- Shared assets that change hands between shifts.

Featured Technologies:

Barcode

Most inventory control and data collection methods are based on barcode technology. Barcode systems use manual scanning to collect data and update inventory records in your back-end systems. Assets and inventory are scanned throughout various checkpoints to validate SKUs and keep an updated digital record of inventory movements.

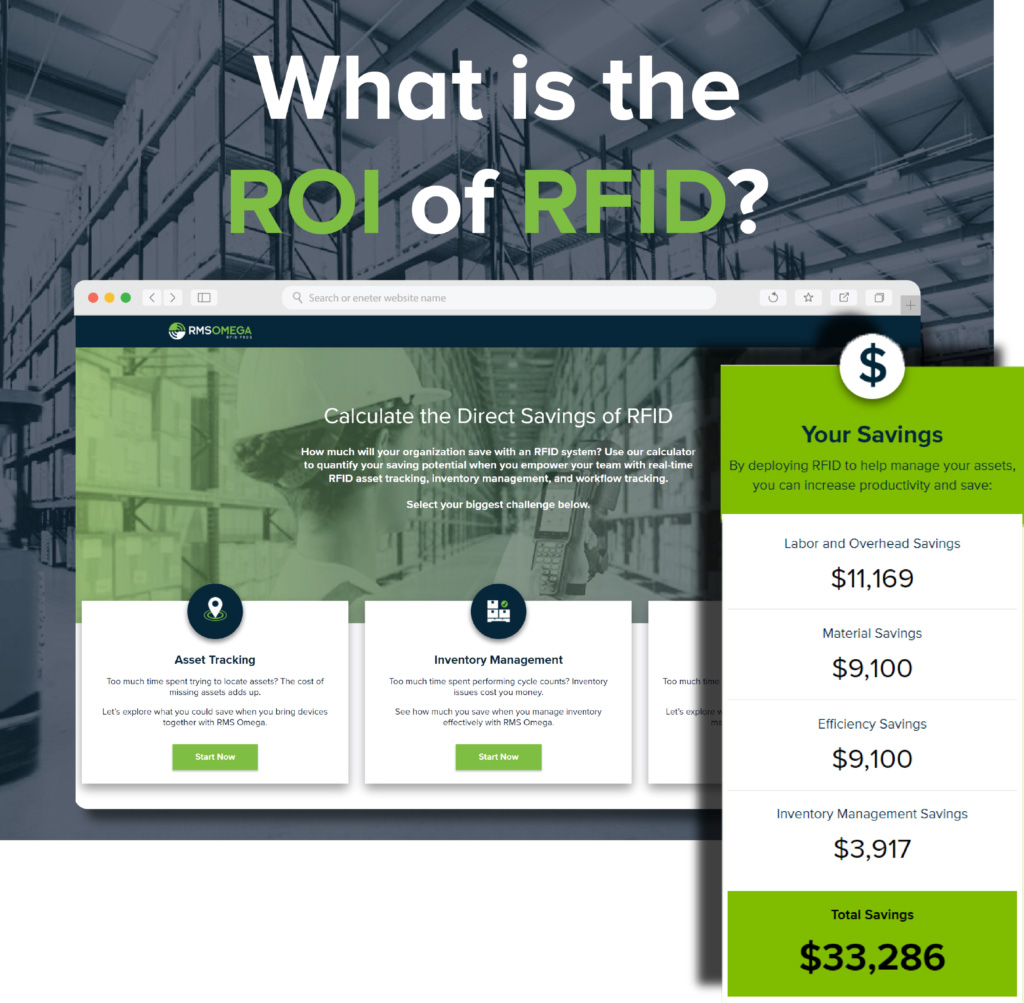

RFID

RFID technology offers greater location tracking than traditional barcode data collection. In an RFID solution, fixed or handheld readers pick up radio frequency signals from tagged items. Due to the technology’s inherent benefits, data can be collected without a line-of-sight scan or any manual scanning at all.

RTLS

Real-time location systems provide even greater automation and data frequency than RFID. RTLS tags actively transmit location data in real time. Active location technology includes Ultrawideband (UWB), Bluetooth, and GPS. All of which use sensors to triangulate precise locations on high-value assets.

Benefits of Location Tracking Solutions

An accurate location tracking system provides precise and accurate location data at all times. In turn, enterprises can achieve a greater level of visibility and data accuracy in order to make more informed decisions regarding the movement of raw materials, inventory, equipment, personnel, and processes.

Our technology experts will work with you to evaluate your current technology, business processes, challenges, and budget in order to design a location-tracking solution that works for you. When you work with us, you work with more than just a vendor. RMS has over 20+ years of premier partnerships and industry expertise to help solve any business challenge. We take pride in offering a total solution that combines the best hardware, software, and support in order to achieve the results you desire.