Connected Workers Using Connected Technology to Streamline Business Processes

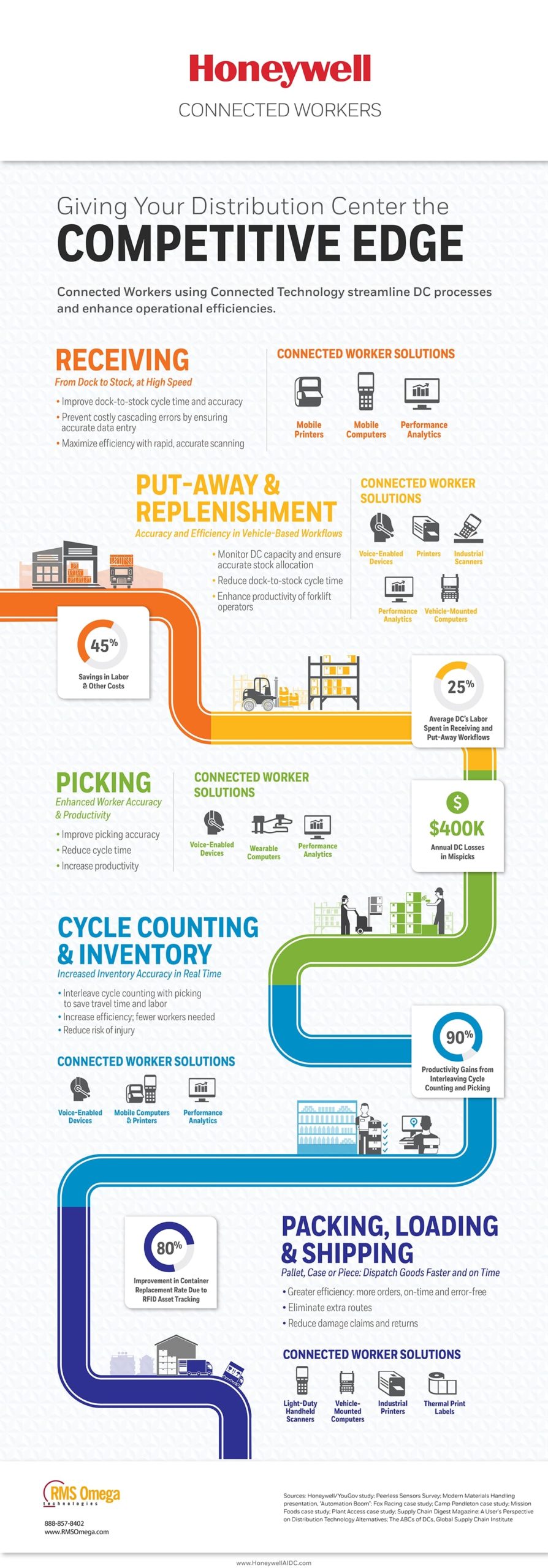

Connected workers using the right technologies can streamline distribution center processes and enhance operational efficiencies. There are so many benefits to using connected technology in all areas throughout distribution centers. See the infographic below to learn more about the benefits of using connected technology in different areas of distribution centers.

Connected Technology Throughout Distribution Centers

As you can see, connected technology makes it easy to track items as they travel through the distribution center. From receiving to shipping, you will always know where each item is. All while saving time when using the right technology.

Receiving

From the moment you receive items on the dock, you should start the tracking process. With connected technology, you are able to improve dock-to-stock cycle time and accuracy, prevent costly cascading errors by ensuring accurate data entry, and maximize efficiency with rapid, accurate scanning.

Recommended solutions include mobile printing, mobile computing, and performance analytics. Companies who have used these technologies have seen drastic savings in labor and other costs.

Put-Away & Replenishment

With the use of connected technology, you will see an increase in accuracy and efficiency in vehicle-based workflows. As a result, you will be able to better monitor distribution center capacity and ensure accurate stock allocation. Also, you will be able to reduce dock-to-stock cycle time and enhance the productivity of forklift operators.

Technologies we recommend for use in put-away & replenishment include voice-enabled devices, printers, industrial scanners, performance analytics, and vehicle-mounted computers. As a result, companies have seen less labor time in both receiving and put-away workflows.

Picking

Use the right technology to enhance worker accuracy and productivity. Companies using connected technology see an improvement in picking accuracy, a reduction in cycle time, and an increase in productivity.

Technology solutions we recommend for picking include voice-enabled devices, wearable computers, and performance analytics. As a result, you will see less money lost due to mis-picks.

Cycle Counting & Inventory

You will see increased inventory accuracy in real-time when you use connected technology for cycle counting and inventory. You will see interleave cycle counting with picking to save travel time and labor. Also, you’ll see results such as reduced risk of injury and increased efficiency.

We recommend solutions such as voice-enabled devices, mobile computers, mobile printers, and performance analytics. Companies that have used these solutions have seen high productivity gains.

Packing, Loading, & Shipping

Whether you’re shipping a pallet, case, or piece, you will be able to dispatch goods faster and on time. You’ll see greater efficiency – more orders will be on time and error-free. In addition, you’ll see the elimination of extra routes, as well as reduced damage claims and returns.

Recommended solutions include light-duty handheld scanners, vehicle-mounted computers, industrial printers, and thermal print labels. As a result, distribution centers that used these solutions have seen improvement in container replacement rates.