Give Your Distribution Center the Competitive Edge

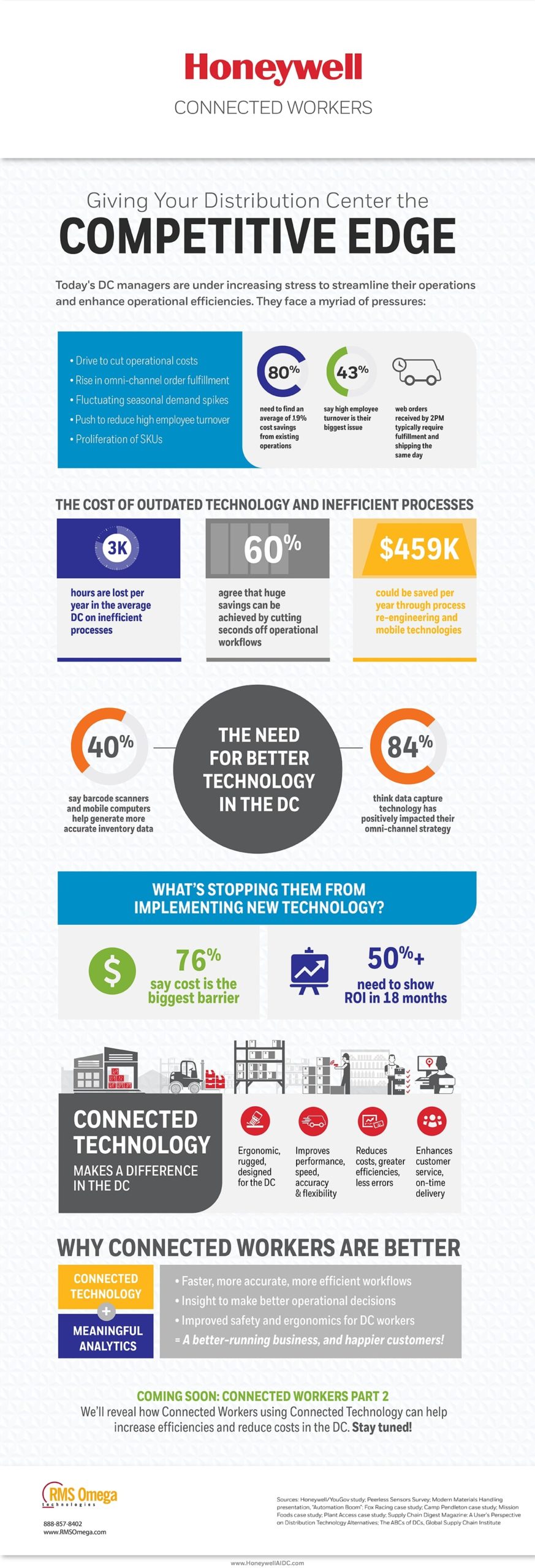

Distribution center managers are under great amounts of increasing stress; they’re pressured to streamline their operations and enhance operational efficiencies. This can become a difficult task unless you’re using the right technology! See the infographic below to discover why it is so important to use the right technology and how connected workers can improve your distribution center operations.

Who are Connected Workers?

The connected worker results in better running business and happy customers. Who wouldn’t want that?

A connected worker is an employee who uses technology to help them connect to other employees as well as real-time information. As a result, you will have faster, more accurate, and more efficient workflows. They use the technology to produce meaningful analytics to help improve safety and ergonomics for distribution center workers which will give your employees insight to make better overall operational decisions.

Use Connected Technology to Gain Connected Workers

Connected technology makes a huge difference in the distribution center. Features and benefits of using connected technology include:

- Ergonomic, rugged devices designed for the distribution center

- Improved performance, speed, accuracy, and flexibility

- Reduced costs, greater efficiencies, and fewer errors

- Enhanced customer service and on-time delivery

The Cost of Using Outdated Technology in the Distribution Center

Using outdated technology in industrial environments can have more harm than good. As time goes on, technology continues to improve. Using technology that is more than 5 years old can hold your distribution center back and you will lose your competitive advantage. As a result of using outdated technology, your processes will become inefficient which can be harmful. Due to inefficient processes, approximately 3,000 hours are lost per year in the average distribution center. In addition, 60% of distribution center managers agree that huge savings can be achieved by cutting off just seconds of operational workflows.

Many people believe they’re saving money by using technology they already have. However, old and outdated technology causes processes to be less efficient. As a result, inefficient processes are costing distribution centers an average of $459,000 a year! So, make sure you save that money by using the most up-to-date technology.

Technology Designed for the Distribution Center

In many distribution centers, there is a need for better technology. Distribution centers throughout the country see positive results after implementing a better technology solution. About 40% of managers say barcode scanners and mobile computers help generate more accurate inventory data and 84% think data capture technology has positively impacted their omnichannel strategy. So, it seems like a no-brainer – make sure you’re using up-to-date technology designed for distribution centers!

Are you ready to help your distribution center save both time and money while keeping your competitive edge?

Read Our Guide: 10 Considerations When Upgrading Your Mobile Devices