Enhance Visibility Over Operations

In order to remain competitive, manufacturing companies must obtain lean operations by eliminating costs and increasing throughput. By automating data collection throughout your supply chain, you can gain the ability to track vital assets, inventory, work in process, parts and materials, and personnel. This accurate, up-to-date data can inform your day-to-day operating decisions and is essential for long-term proactive planning.

Automated Data Collection & Tracking

![]()

![]() In a manufacturing facility, materials and supplies enter through a receiving dock where they get logged into a tracking system or software platform by scanning their associated barcode label or RFID tag. The data on these labels is unique to the product and might include serial and lot numbers, color, size, vendor, manufacturer, expiration date, and any other pertinent information needed to manage operations.

In a manufacturing facility, materials and supplies enter through a receiving dock where they get logged into a tracking system or software platform by scanning their associated barcode label or RFID tag. The data on these labels is unique to the product and might include serial and lot numbers, color, size, vendor, manufacturer, expiration date, and any other pertinent information needed to manage operations.

RMS Omega specialists have access to industry-leading data collection, tracking, and automation technologies that improve visibility, increase accuracy and throughput, and solve challenges. We have 20+ years of experience in deploying software and hardware solutions utilizing:

- Barcode

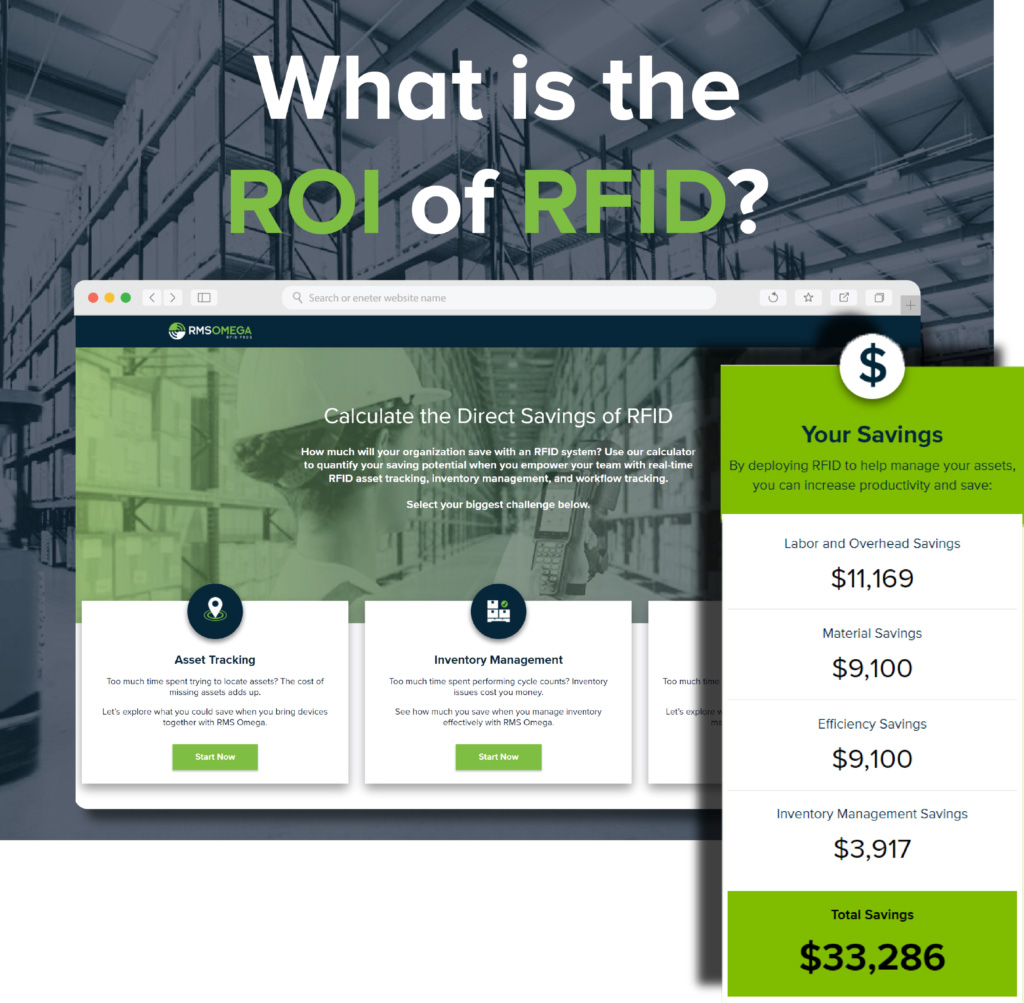

- Radio Frequency Identification (RFID)

- Real-Time Location System (RTLS)

- Wireless Infrastructure

- Mobile Computing

- Voice Automation

Leveraging Real-Time Visibility in Manufacturing

Real-time, accurate data helps manufacturing facilities optimize a variety of workflows by increasing productivity and eliminating inefficiencies. Our solutions provide enhanced visibility in areas like:

- WIP Tracking – Enforce accountable and compliant processes for manufacturing and assembly with reliable RFID and barcode systems.

- Parts & Materials Receiving – Maintain accurate and up-to-date stock of parts and materials. Automatically update inventory once items are received, shipped, or put into production.

- Equipment Monitoring- Monitor assets and manufacturing processes to identify both bottlenecks and proper allocation of equipment.

- Voice-Directed Workflows – Simplify workflows, reduce errors, and boost productivity with voice-guided and voice-directed workflows that operate off of your enterprise mobile devices.

- Process & Workflow Automation – Save time and labor by automating workflows. Automating manual tasks helps organizations eliminate errors and achieve operations that are leaner and more optimized.

The overall result is a lean manufacturing process based on real-time, accurate information. In turn, this accurate data allows workflows to be designed as efficiently and as cost-effective as possible.