Thermal Barcode Printing in Healthcare

When it comes to thermal barcode printing, there are so many options. What makes one thermal barcode printer different from another? How do you know where to use each printer? There are so many questions to ask when it comes time to choose a printer.

A good thermal barcode printer in healthcare will help increase accuracy and patient safety. Printers should help streamline the supply chain and reduce overall healthcare costs while enhancing patient care. Here’s a Zebra printer that can do all of that.

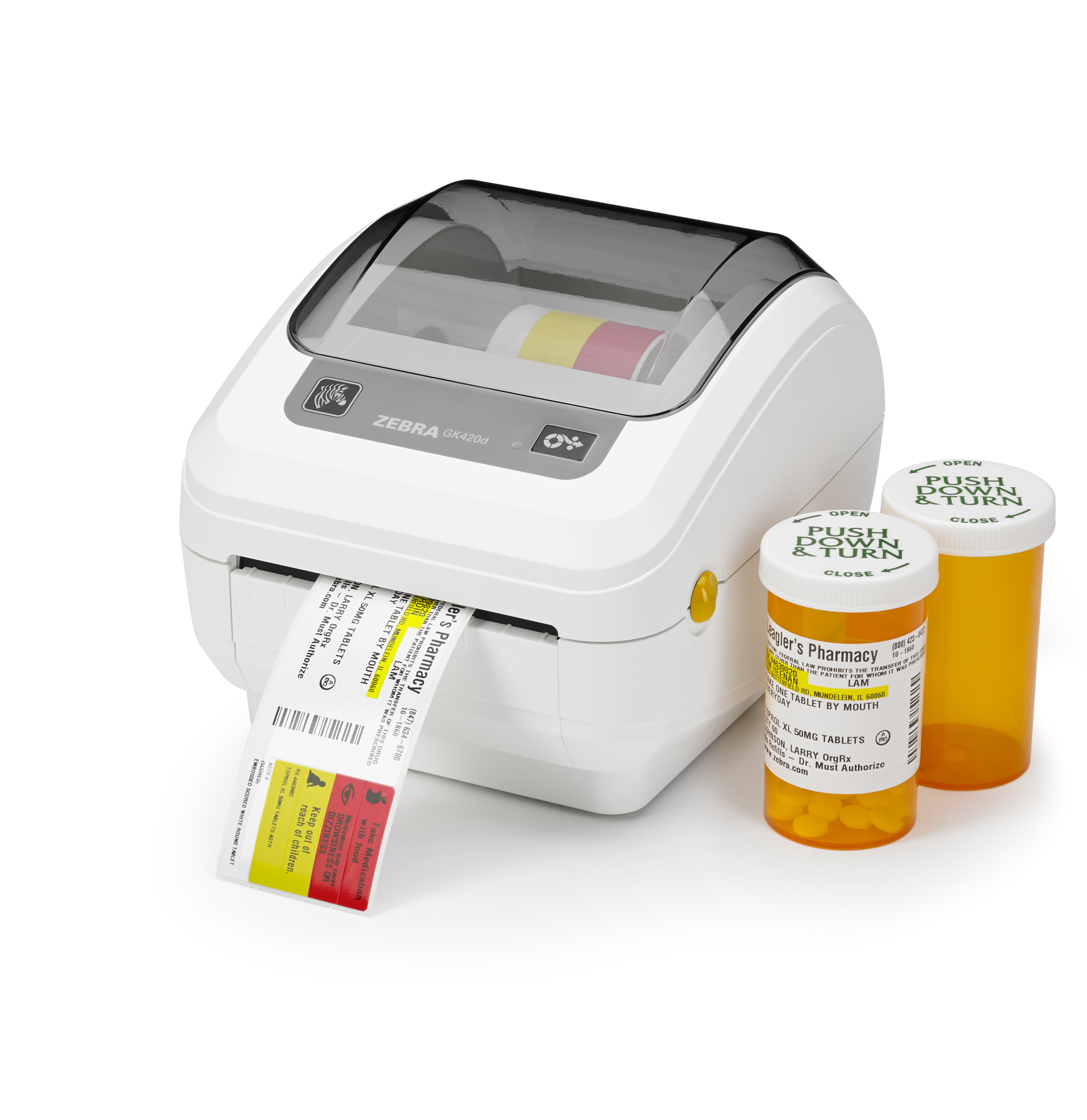

Zebra’s GK420 Healthcare Desktop Thermal Barcode Printer

The GK420 healthcare thermal barcode printer is designed specifically for the healthcare environment. They are constructed with healthcare plastics so they can be cleaned with disinfectants to minimize the risk of infectious diseases. These printers are compact and have a very small footprint so not much tabletop space is needed. Some key features of the GK420 printer include:

- Easy integration – available in both direct thermal and thermal transfer models.

- Reliable performance – constructed with durable, disinfectant-ready materials.

- Adherence to industry standards – designed with a medical-grade power supply.

- Certified for healthcare applications – certified and recommended by all of the leading Electronic Health Records (EHR) providers.

- Space and cost savings – have the smallest footprint of all Zebra’s desktop printers and will reduce operational costs.

- Cleaning made simple – it is safe to clean using many cleaning agent ingredients.

Selecting Direct Thermal or Thermal Transfer Barcode Printers

Since there are both direct thermal and thermal transfer models available, the GK420 can be used in a variety of applications throughout the healthcare industry. Thermal transfer printing typically provides more durable and long-lasting output. Direct thermal printing offers added security in safeguarding patient privacy because this type of printing does not require a ribbon.

- In laboratory and surgery center labeling, we recommend using the thermal transfer model. Labels on specimens may be exposed to harsh cleaning products, sterilization, or extreme temperatures.

- In blood and milk bank labeling, we recommend the thermal transfer model since labels may be exposed to cleaning agents and extreme temperatures.

- In medical records labeling, we recommend using the direct thermal model. Since patient privacy is a huge concern, using a ribbon would mean there is a secondary record of the printed information. Direct thermal printing does not require a ribbon which protects the patient’s privacy.

- In prescription labeling, we recommend the direct thermal model so there is no secondary record of printed information.

- In asset tracking labeling, we recommend using the thermal transfer model since assets may be exposed to harsh cleaning. products and identification of assets may be required for several years.