Background on Retail RFID Mandates

Over the past year, a growing number of retailers have issued RFID tag mandates for their suppliers. The trend comes from Walmart’s 2022 requirement for suppliers to start tagging their products with GS1-certified RFID labels to create a standardized and more transparent supply chain. As more big box retailers follow suit, suppliers are quickly adapting to meet retail RFID mandates and keep their products on the shelves.

What Are GS1 RFID Mandates?

GS1 is a global non-profit that develops universal standards for creating unique identification codes for barcode and RFID data capture. These standards guide things like data formatting, encoding, and placement of tags on packaged products. By enforcing GS1 standards, organizations like Walmart can unify partners throughout its value chain with interoperable RFID systems that collect, store, and exchange RFID tag data. This creates a fully integrated and visible supply chain for retailers with large supplier networks, helping them:

- Increase visibility over inventory.

- Avoid stock disruptions.

- Promote efficiency throughout their supply chain operations.

- Manage the flow of goods to meet customer demand.

Learn More about RFID Retail Mandates

Steps For Meeting RFID Compliance

While RFID mandates deliver considerable benefits for both retail organizations and suppliers, integrating the technology can have some initial complexities. The first challenge suppliers, distributors, and logistics providers face when seeking RFID compliance is selecting the right labels and tags.

1. Tag Selection

RFID Tags play a significant part in the overall success of your RFID implementation and meeting retail compliance. First, tags must meet GS1 standards, meaning they need to encode unique information like Electronic Product Codes (EPCs), Global Trade Item Numbers (GTINs), Serial Numbers (SNs) and meet other formatting and tag placement requirements when products are shipped to retail stores.

At the same time, different RFID tag types may need to be tested to ensure they can be reliably and accurately read in your environment and for your specific tagging application. Elements like liquids, metals, and high carbon can skew RFID reads, throwing off the accuracy of your counts. Fortunately, our team of RFID experts is adept at testing different tag types and overcoming environmental obstacles to design a solution that produces optimal reads.

Other Tagging Considerations

Inlay Specs – RFID inlays contain the antenna and chip that host the data about your specific product. Walmart and other retailers have approved lists of tested inlays for each product type and detailed requirements about inlay size and format.

Tag Placement – Per retail mandates, RFID tags need to adhere to the sides of product packaging. Tags cannot be placed on the bottom of products since contact with metal shelving will disrupt store counts. Furthermore, tag placement will greatly depend on the type of product packaging.

Packaging – Packaged products must have the RFID tag’s Electronic Product Code (EPC) displayed outward for store associates and customers to see. Tag formats are also suspected to change based on packaging dimensions and materials.

Other Tag Requirements – Big box retailers also have a list of miscellaneous requirements regarding RFID tagging that suppliers must be cognizant of.

- RFID tags must be removable by the customer.

- Tags cannot be integrated into the product.

- Tags and inlays cannot cover any text or images.

- Tags must have a durable adhesive.

With all of these stipulations and future changes, it is important to work with a label provider that can provide consultation and testing for different tags to work with your unique products while meeting GS1 mandates.

2. Creating Your GS1 Tags

Once you have confirmed your label type, design, and format, the next step is to decide between producing your tags in-house or utilizing a pre-print service. Fortunately, we can help suppliers with either option.

Printing In-House

Printing labels in-house with your own RFID printers and encoders offers greater flexibility and complete control over your label runs. However, in-house printing requires some additional pieces of hardware and software to get up and running.

- RFID printer/encoder

- Media – labels, tags, and other print supplies

- Label design software

- Printer software

Using Pre-Print Services

Alternatively, organizations can opt for pre-printed labels, where a service provider like RMS Omega source the labels, and print, encode, and ship batches of serialized RFID tags for your products.

3. Validating Tags with an RFID Reader

Now that you have GS1 complaint tags on your products, you can fully leverage the power of RFID technology. Not only can you meet retail compliance and avoid chargebacks, but RFID tags can be leveraged to provide better visibility to your own business operations. Using a handheld RFID reader will scan hundreds of product tags in an instant, enabling you to:

- Quickly perform inventory counts and audits.

- Instantly verify inbound products.

- Confirm SKUs and quantities in shipments to retailers.

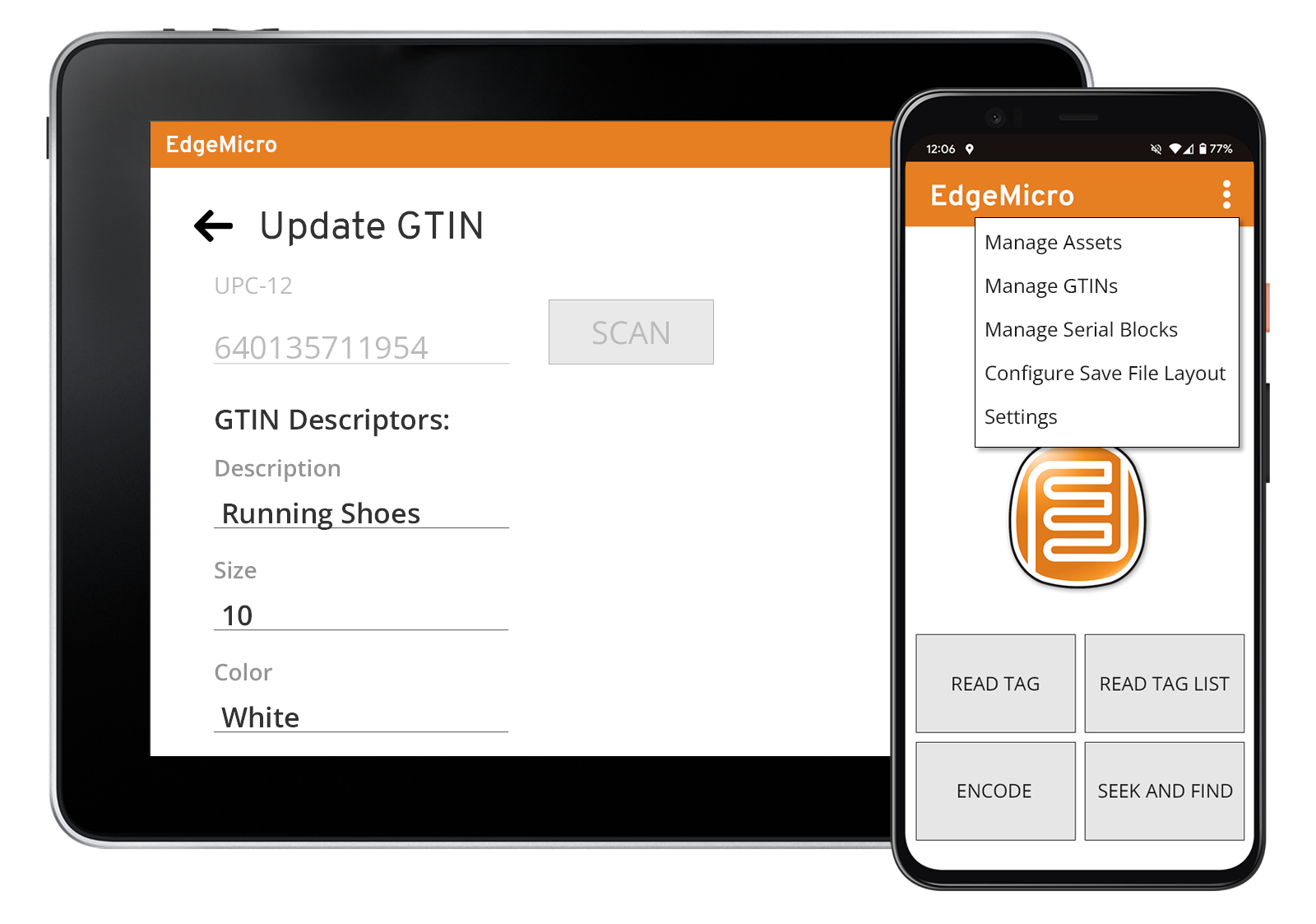

4. Collecting & Storing Your Data For Compliance

While handheld RFID readers act as a vehicle for data collection, RFID software makes it possible to collect, view, store, and export data regarding your shipments. Not only does RFID software document compliance, but it provides additional value-add by:

- Verifying that RFID and EPC encoding matches UPC (Universal Product Code).

- Ensuring all tags in your order are valid.

- Avoiding returns, chargebacks, and failed compliance.

- Automating data collection and storage.

5. RFID Checkpoints & Shipment Tracking (Optional)

For larger-scale operations, fixed RFID portals can replace handheld readers – validating entire pallets and shipments as they pass through dock doors. Furthermore, RMS Omega provides shipment tracking software that integrates with RFID portals, creating a complete supply chain visibility solution as products move between facilities. With a complete RFID shipment tracking solution, you can:

- Receive delivery confirmations in real-time.

- Identify incomplete shipments before departing.

- Get real-time mobile notifications on shipment schedules and delivery statuses.

- Adhere to shipment schedules.

The Value of Integrating RFID & Its Potential ROI

While GS1 RFID mandates may initially seem like a burden for suppliers, 3PLs, and other players in the retail value chain, integrating RFID technology can deliver valuable benefits. Not only has the cost of UHF RFID tags dropped 80% over the past two decades, but the technology has proven to deliver considerable cost savings and efficiency enhancements to operations. Automating data collection with RFID improves the accuracy of operations by eliminating manual errors, and it creates greater transparency over inventory levels.

At the retail level, the technology is dramatically improving SKU-level accuracy – creating visibility over the movements of merchandise in returns, exchanges, buy online, pick up in-store, and other omnichannel practices today’s brick-and-mortar stores have adopted.

On the other hand, RFID can help suppliers improve visibility and accuracy within their own operations. By using RFID for accurate inventory control, asset tracking, cycle counts, audits, and more, organizations can save considerable labor, time, chargebacks, lost business, reconcile errors, and more.

Savings Calculator: See How Much Cost You Can Cut with RFID

Complete RFID Solutions From a Single Source

Becoming RFID compliant can be challenging for 3PLs and suppliers to manage on top of their daily operations. Additionally, selecting the correct labels and tags that meet WalMart and other retailer requirements can be a cumbersome process that requires testing and familiarity with RFID implementations. Fortunately, RMS Omega has decades of integration expertise and premiere partnerships with leading RFID hardware, software, and label providers. When you partner with RMS Omega to comply with an RFID mandate, you work with a single source that provides:

- Comprehensive RFID expertise, product knowledge, and recommendations.

- Tag testing to ensure that the tags meet the retailer’s requirements and your own organization’s standards.

- Supporting hardware, software, and professional services to streamline the RFID deployment process.

- In-house support and project management teams focused on your successful deployment.

- Out-of-the-box GS1 RFID bundles that plug and play into your operations, helping you achieve compliance quickly.