RFID: What is it?

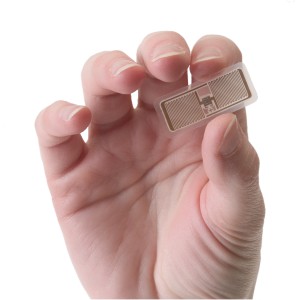

RFID is an acronym for radio-frequency identification. It is a technology where data encoded in smart labels or tags is captured by a reader via radio waves. Also, RFID tag data acquires the ability to read outside of the line of sight.

When a company is choosing an RFID tag, there are many factors to take into consideration. The frequency of the tag if often overlooked. There are low-frequency tags, high-frequency tags, and ultra-high-frequency tags, otherwise known as LF, HF, & UHF. Radio waves have a different behavioral pattern at each of these frequencies and there are advantages and disadvantages associated with using each frequency.

Low-Frequency (LF)

The low-frequency band is able to cover frequencies from 30 KHz (Kilohertz) to 300 KHz. Usually, low-frequency RFID systems operate right around 125 KHz. The low-frequency band has a slower read speed than higher frequencies, but it has a greater ability to be transmitted or received in all directions. This frequency band provides a short read range of only 10 cm, but it is not very sensitive to radio wave interference. LF can be used in moist situations, also LF RFID transmission accesses tags behind thin-metal substances. Finally, low-frequency RFID applications can be used for access control and livestock tracking, which is a great benefit.

High-Frequency (HF)

The high-frequency band is able to cover frequencies from 3 MHz (Megahertz) to 30 MHz.As a result, high-frequency RFID systems operate around 13.56 MHz. High-frequency systems tend to experience moderate sensitivity to radio-wave interference. HF bands can also operate in moist conditions. High-frequency RFID has the use for data transfer applications, ticketing, and payment. There are several HF standards in place, including the ISO 15693 standard for tracking items, the ISO/IEC 14443 A and ISO/IEC 14443 standards for MIFARE technology, which is used in proximity and smart cards. There are other standards that are used for near field communication, electric money cards, and more.

Ultra-High Frequency (UHF)

The ultra-high frequency band is able to cover frequencies from 300 MHz to 3 GHz (Gigahertz). The read range of the UHF is up to 12 meters, which is 40 feet. As a result, ultra-high frequency systems operate around 900 to 915 MHz. The UHF RFID has a much quicker data transfer rate than LF or HF. Out of the three frequencies, the ultra-high frequency is the most sensitive to interference.

Product manufacturers of UHF design readers, tags, and antennas to keep the performance relatively high even in the most challenging environments. Also, UHF tags are cheaper and easier to manufacture than LF/HF tags. Above all, UHF is the fastest-growing segment of RFID technology. The application of ultra-high frequency technology expands to many markets including:

![]()

- Life science

- Retail

- Healthcare

- Manufacturing

- Pharmaceutical

- Anti-counterfeiting

- And more!

The Current Trend in RFID

Finally, the ultra-high frequency creates the most value. It is the fastest-growing segment of the RFID market, and the majority of new projects are using ultra-high frequency. UHF systems generate long read ranges (40 feet), whereas the other frequencies have much shorter ranges. Other benefits of UHF RFID include:

- Fast data transfer rate

- Increases inventory visibility

- Automates workflows

- Prevents the use of recalled/expired products

- Reduces shrinkage and prevents inventory stock-outs

- Improves overall business operations

- And much more!