Warehouse Scanning & Data Collection Technology

Scanning in the warehouse is essential. Each process requires different warehouse scanning equipment and each facility has its own unique requirements.

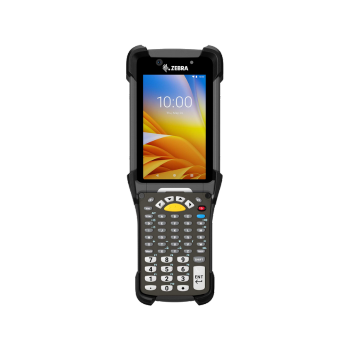

Using the right warehouse scanning equipment can maximize throughput, increase productivity, and improve accuracy in warehouse and distribution center operations. These purpose-built barcode scanners and mobile computers are rugged enough to withstand the harsh warehouse environment while providing exceptional scanning and mobile computing power. They will also support real-time data capture at the point of transaction to ensure accuracy.

RMS Omega offers a wide variety of warehouse scanning equipment for key workflows, such as receiving, replenishment and putaway, picking and fulfillment, packing and shipping, inventory control, and more.

View Our Top Warehouse Scanner Gun Options

Warehouse Scanning Equipment for Different Applications

Stock Receiving

Inventory receiving is essential for any warehouse or distribution center. All other workflows depend on the accuracy of the receiving process so accurate data entry is crucial at this phase to prevent costly cascading errors. Distribution centers require warehouse scanning equipment that can connect in real-time, can withstand high-volume scanning, and can read barcodes that are damaged or difficult to read.

Industrial scan guns and wearable scanning are good options for receiving. Warehouse scan guns are specifically built for industrial environments, so they are extremely rugged. Rugged mobile computers and scanners can read virtually all 1D and 2D barcodes from 6 inches to 50 feet away. They are perfect for high-volume scanning, which is one reason they are a great fit for receiving.

Replenishment & Put Away

A pallet’s initial location will influence all proceeding processes. A WMS system can help with that, but only if it’s running on the right equipment. You’ll need warehouse scanning equipment to accurately confirm the transaction by rapidly scanning a location label.

Scanners in this application also need to be built for industrial environments with fast scanning capability, unmatched motion tolerance (up to 500 inches per second), and support for omnidirectional scanning. These barcode scanners need to operate in hot and cold temperatures and withstand constant forklift vibrations. These devices also usually have a comfortable grip to maximize operator efficiency.

Selection & Picking

Picking is the most labor-intensive process in warehouses and distribution centers. Selection and picking need to be a fast and accurate process. You’ll need warehouse scanning equipment that can eliminate causes of inefficiencies.

Wearable mobile computers and ring scanners are very helpful in the picking process. You’ll want to have a high IP rating and drop specification with the optimal combination of performance and usability to meet the needs of the user and the demands of a warehouse or distribution center environment. Contact us for more information on selecting a rugged mobile device or wearable device.

Packing & Shipping

Packing stations and pallet-building areas require speed and precision to complete and ship orders. In packing and shipping operations, warehouse scanning equipment must be responsive, accurate, and ergonomic.

Industrial barcode scanners and handhelds enable workers to easily shipments. Lean on industry-leading rugged warehouse scanning for reliable full-shift performance and optimized barcode scanning.

Warehouse Inventory Control

Inventory control operations throughout warehouses and distribution centers are vital to the accuracy of overall inventory. Use the right warehouse scanning equipment to conduct an inventory in real-time, eliminating costly efforts and errors that you may have with periodic manual counts that are conducted via time-consuming paper and data-entry processes.

We recommend using the CK series by Honeywell for inventory control. These devices are ultra-rugged mobile computers that feature quick and accurate scanning. It gives employees access to real-time data and has a rapid response time.

Browse Our Warehouse Scanning Options

Our team has decades of expertise in integrating and supporting mobile data capture technology. From touchscreen handhelds, rugged scan guns, wearable devices, and more. We provide unbiased strategic technology solutions centered around your unique needs and focused on delivering your desired business outcomes.