Implementing an RFID Asset Tracking Solution

By monitoring your critical equipment with an RFID asset tracking solution, you can keep a detailed chain of custody that will help you optimize the utilization of assets and prevent loss throughout your organization. Asset tracking can be implemented for a variety of enterprise items like equipment, parts and materials, and IT. Whether you plan to use RFID for check-in/check-out, monitoring items as they pass through zones in a facility, or locating items on a case-by-case basis, RFID asset tracking solutions provide the following benefits:

- Reduced time spent on searching for assets.

- Minimizing lost and stolen assets.

- Higher productivity by preventing production stoppage.

- Creating an improved chain of custody and compliance process.

- A better picture of asset utilization & operation efficiency.

Benefits of an RFID Asset Tracking Solution

1. Increased Asset Visibility

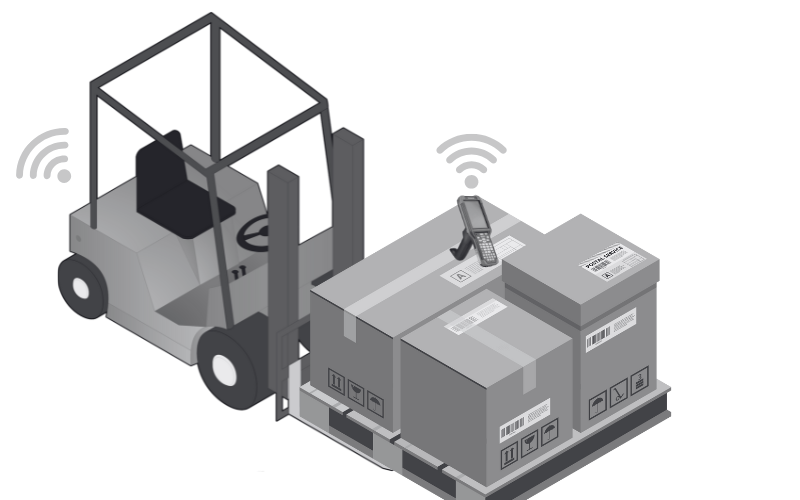

RFID technology can track a large variety of different assets. RFID supplies information in real-time without a direct line of sight in order to retrieve data. This is the most efficient and accurate way to manage information about your valuable assets, reducing the time that’s spent searching for them.

Using RFID, you gain the most accurate picture of asset utilization data and operational efficiency.

2. Increased Productivity

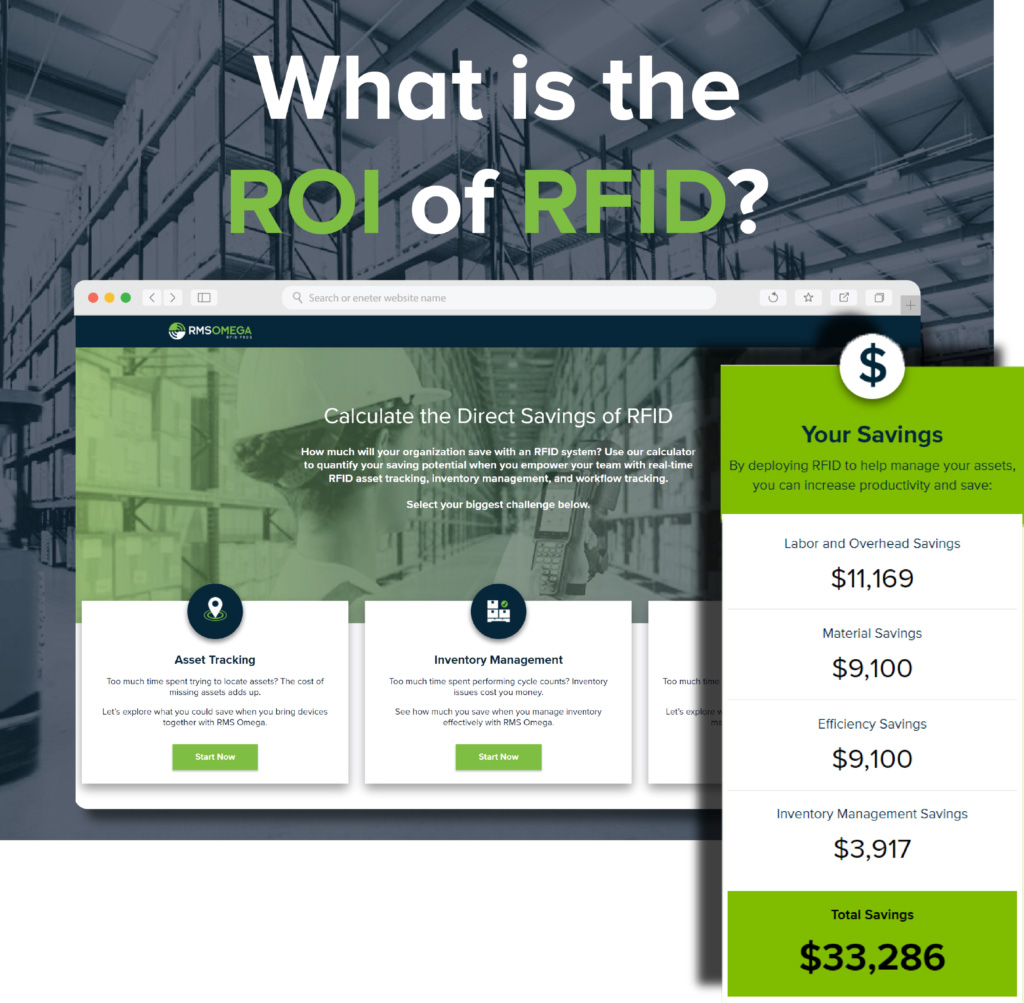

Tracking the movement of company assets allows management to easily identify bottlenecks in operations. As a result, businesses can prevent delays and save on unnecessary labor costs. Asset tracking makes sure that products move efficiently and adhere to strict delivery schedules. RFID and asset tracking tighten up the supply chain and deliver exceptional cost-saving benefits. Asset tracking solutions also prevent the accrual of unnecessary costs while delivering valuable analytics that can promote better managerial decisions.

3. Minimized Loss

Asset tracking is a paramount tool within organizations that send and receive equipment or receive a high volume of returned goods. Assets that are missing or unaccounted for can have a big negative impact on a business’s bottom line. Businesses can keep tabs on inventory when it is distributed, stocked, relocated, delivered, or returned. Additionally, RFID can provide a host of other information outside of locations like quantity and even the conditions of merchandise.

Building An RFID Asset Tracking Solution

RFID asset tracking allows you to create a fully visible picture of the items moving around a facility and throughout an entire enterprise. Our team of RFID experts will help solve your tracking challenges by working with you to design, test, implement, and support a solution that allows you to monitor the flow of critical tools, personnel, parts, and materials.

Ultimately, our goal is to provide customers with a complete asset-tracking solution that makes operations more accurate and transparent. When you work with RMS Omega, we will be your one-stop for industry-leading RFID hardware, software, tags, service, and knowledge.