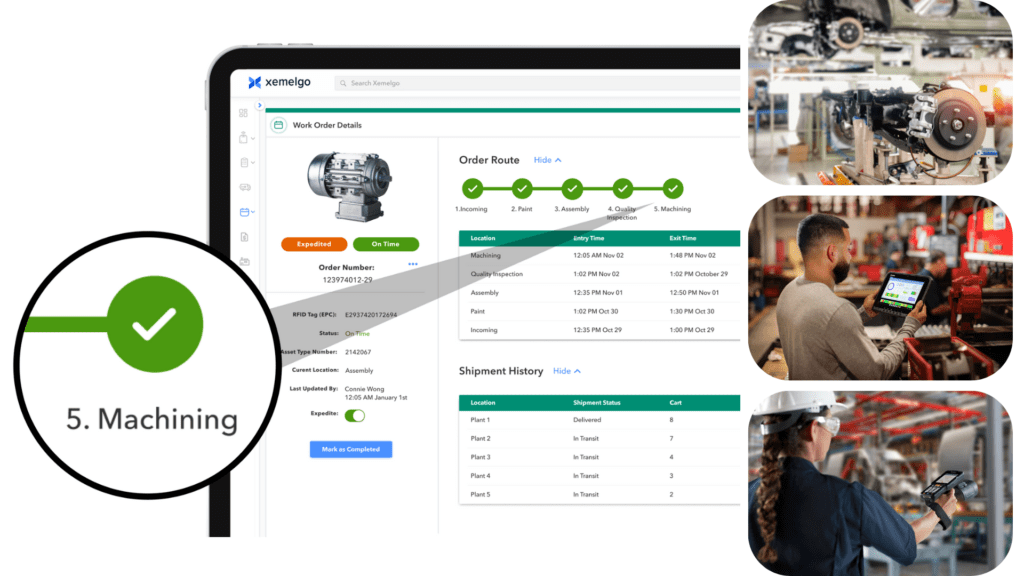

Track Workflow Progression with RFID Work in Process

With RFID, you can monitor your manufacturing processes, materials, and workflows – helping you make products efficiently and on time. RFID work-in-process (WIP) tracking prevents errors, creates greater traceability, and promotes accountability through a digitized and automated chain of custody. Furthermore, using RFID for WIP tracking can also reduce hidden operating costs tied to inventory, labor, and overhead.

RFID Work In Process Applications

RFID Work In Process Applications

Reduce lost materials, delayed product movements, and quality assurance errors that result in manufacturing by creating an automated, digital tracking system. RFID technology empowers you to increase visibility into key areas of your operations.

Quality Assurance & Compliance

Passive RFID solutions can verify parts, materials, and equipment as they pass through certain checkpoints, creating an automated method for organizations looking to monitor compliance and quality during production. An RFID tracking solution can also prompt employees when materials are in the wrong work area, station, or conveyor. Alerts and notifications can trigger whenever inventory and assets reach checkpoints within your process or when workflows are completed.

Raw Materials & Parts Tracking

Pinpoint the location of critical parts and materials and identify where they are in the production pipeline. Track the movement of assets and inventory levels in real time throughout your facility. In turn, shortages and overstocks can be prevented, keeping production optimized.

![]()

Identify Bottlenecks Within Your Operations

Get clear visibility throughout your organization’s operations to improve the flow of materials and identify bottlenecks. Track items and materials throughout their entire lifecycle and record the moment they enter each facility to the time it’s ready to ship out to a new location.

Building An RFID Work In Process Solution

RFID work in process allows you to create a digital chain-of-custody and progression tracking over key workflows. To start designing an RFID work in process system, our team of experts will conduct an onsite visit to get a better idea of your facility’s unique layout, challenges, and processes. This allows our team to design a complete WIP tracking solution that will deliver a high degree of accuracy and visibility into your operations.

Ultimately, our goal is to provide customers with a complete RFID solution that makes operations more accurate and transparent. When you work with RMS Omega, we will be your one-stop for industry-leading RFID hardware, software, tags, service, and knowledge.