Precise Inventory Management Systems with RFID

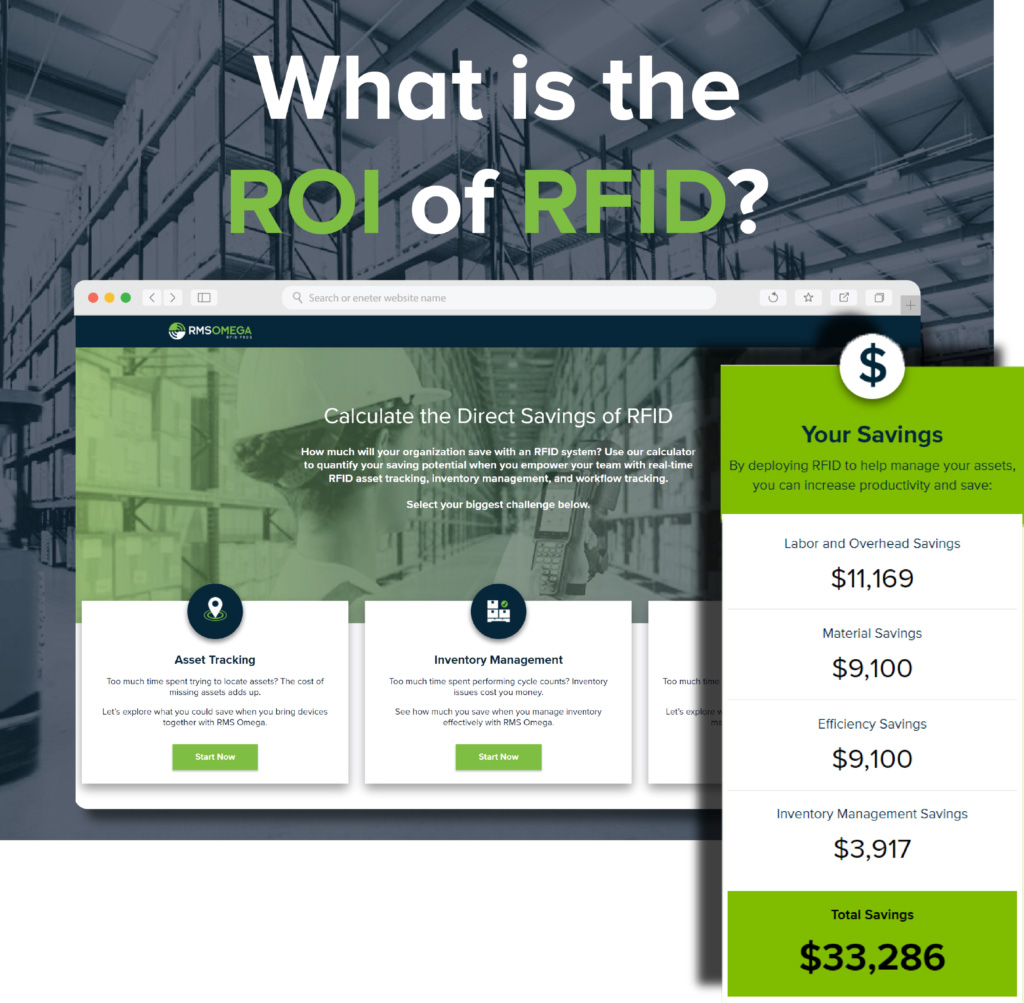

RFID solves inventory management challenges by automating processes and improving the accuracy of data collection. RFID technology streamlines all of your inventory tasks, which lowers costs and time while increasing productivity and accuracy in your operations.

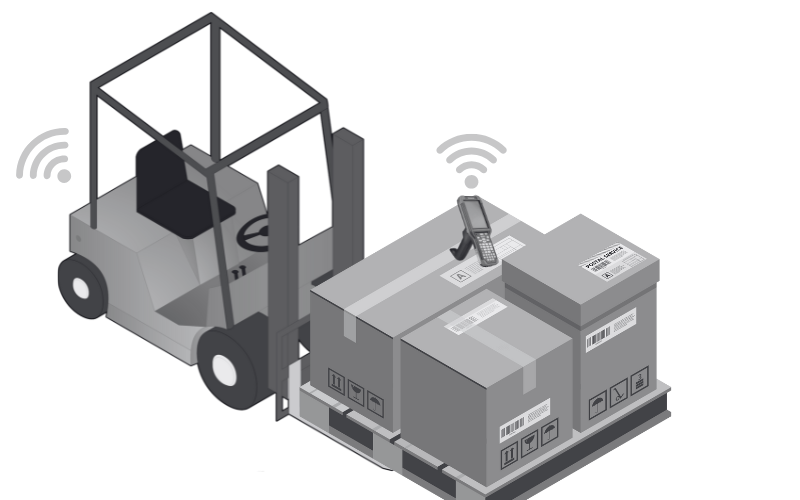

Automating Shipping and Receiving

An RFID solution can automate processes such as shipping, receiving, inventory updates, and other scanning tasks so you can allocate labor toward other areas of operations.

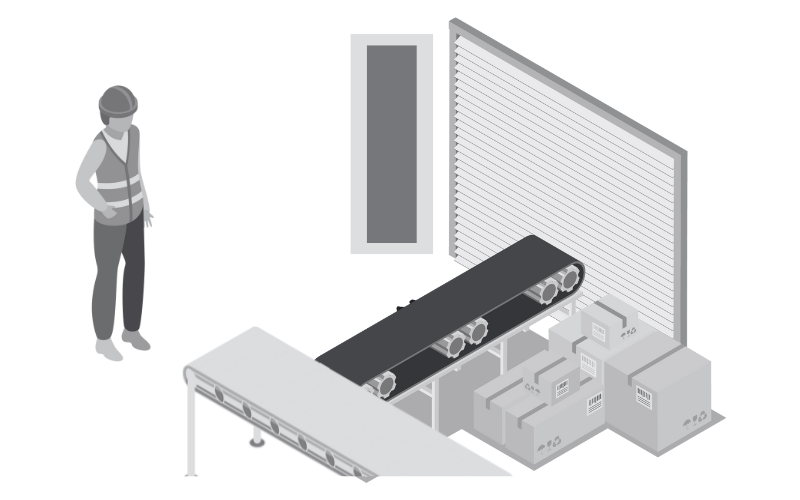

With RFID portals stationed at dock doors, you can eliminate the guesswork by automating inventory during inbound and outbound processes. Instantly verify the products and quantities as they pass through checkpoints. More importantly, RFID solutions can identify errors during shipping, receiving, and inventory, helping your facility become more accurate and achieve fast ROI.

Streamlining Inventory Audits & Cycle Counts

Manual inventory processes are outdated and prone to errors. Empowering your team with mobile RFID readers gives them the ability to verify entire racks and pallets of tags all at once, with a high level of accuracy and efficiency. These kinds of solutions are beneficial for inventory cycle counts as well as honing in on an item’s precise location.

Benefits of Using RFID for Inventory Management

Strategically utilizing an RFID technology solution to enhance inventory visibility can bring the following benefits:

- Less time spent on inventory counts & audits

- Instant verification of inbound & outbound inventory

- Automated warehouse workflows

- Greater visibility over inventory level & location

- Better stock-level management

- Faster location of products