Improve Operations with RFID

Today’s highly automated manufacturing processes require reliable tracking o f materials, parts, and goods along the entire supply chain. Supply chains that move a high volume of goods can result in complex processes and poor visibility. Asset identification and location tracking with the help of RFID technology increases the overall efficiency of operations.

f materials, parts, and goods along the entire supply chain. Supply chains that move a high volume of goods can result in complex processes and poor visibility. Asset identification and location tracking with the help of RFID technology increases the overall efficiency of operations.

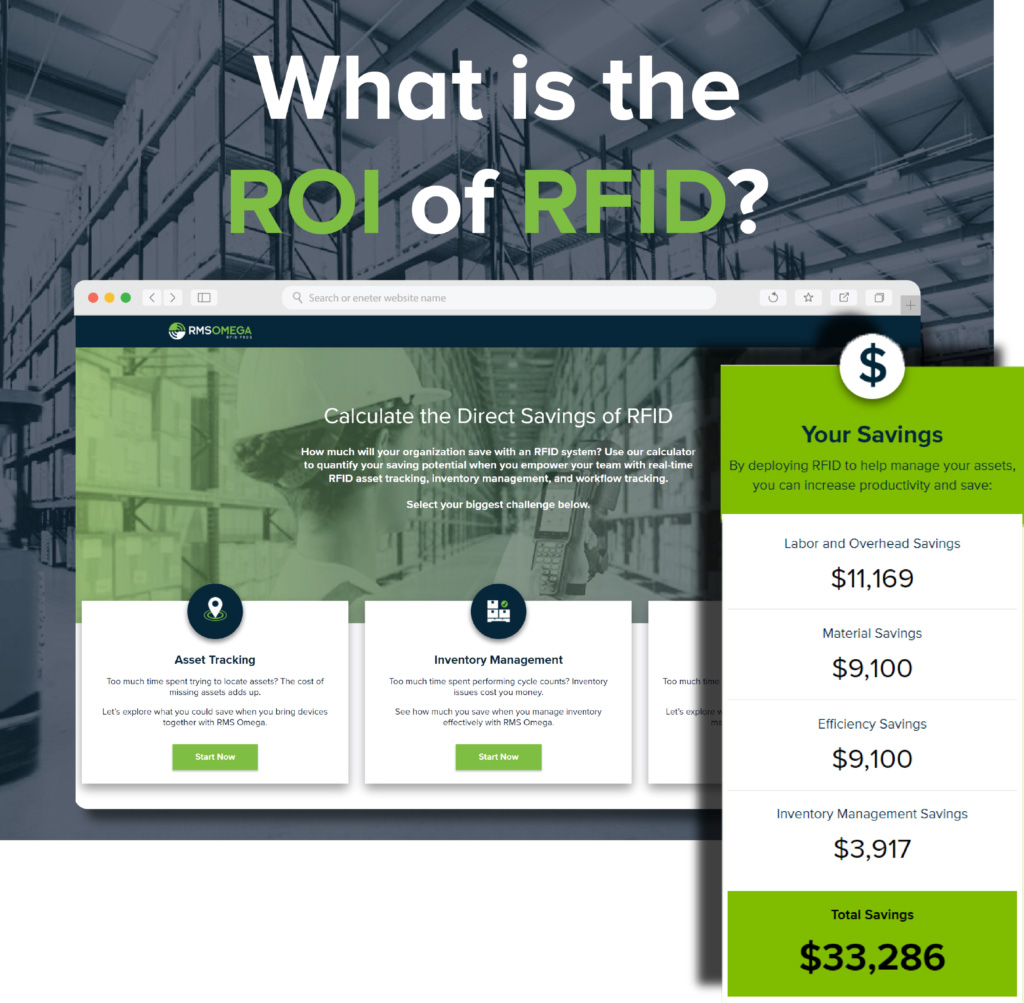

RFID drives efficiency across the entire supply chain of a business. Due to the on-demand economy that surrounds us, fast-paced manufacturing and distribution have become paramount. As a result, RFID and real-time location tracking make businesses more competitive in the marketplace by gaining access to the most accurate data. Give your business a competitive advantage by reducing order time and eliminating wasted tasks when you deploy a custom RFID solution from RMS Omega.

Enhanced visibility in the Manufacturing Process

- Work in Process Tracking: Monitor products or raw materials as they pass through different steps in a process. Enforce compliance and tracking stages of production with ease.

- Inventory Visibility: Automate inventory counts and workflows throughout your value chain with RFID inventory management solutions.

- Asset Tracking: Utilize RFID with a combination of barcode-based technology applications to efficiently track multiple types of assets across an entire organization with real-time accuracy

- Real-Time Location Systems (RTLS): Pinpoint the movement and location of assets, inventory, and personnel with real-time location systems and RFID.

- Check-in/Check-Out: Eliminate time-consuming paper systems or enhance your barcode-enabled check-in / check-out processes with RFID.

Benefits of RFID Solutions in Manufacturing

RFID technology can take your manufacturing operations to the next level by:

- Improving efficiency and lowering operating costs by minimizing lost assets and wasted products.

- Easily identify errors with a completely visible supply chain.

- Improve inventory accuracy with RFID tags and readers that don’t need a direct line of sight

- Real-time information enables just-in-time manufacturing with improved timing and use of assets to reduce customer wait time.