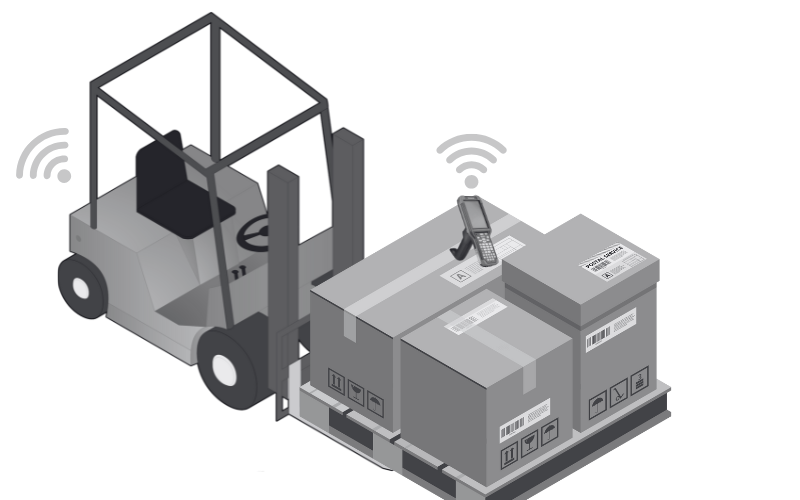

Track Large Volume Movement with Fixed RFID Readers

With fixed RFID readers, you can quickly and accurately track large volumes of RFID-tagged cases, pallets, and items. Fixed RFID technology is ideal for use in high-density tag environments, high throughput applications, and on RF-challenging materials.

![]()

How Fixed RFID Works

Stationary readers are to be strategically placed in order to scan passive RFID tags as they come within their range. Fixed readers identify objects as they move through specific checkpoints in your process, like a dock door, manufacturing station, or conveyor.

Fixed RFID systems also require antennas. Antennas provide the vital link between the fixed reader and tag, moving data back and forth. Antennas allow communication to occur, enabling organizations to capture, exchange, and manage critical information to and from every point of operation.

The great thing about using fixed readers is that there is no need for human intervention. Fixed RFID readers read tags automatically when the tags pass through, without any manual intervention.

Benefits of Using Fixed RFID Technology

Deploying fixed RFID technology simplifies high-volume inventory and materials flow. Therefore, reading tags on large quantities and entire pallets as they move throughout operations improves overall accuracy. Bring visibility into how inventory, assets, and materials move throughout your operations while saving on critical errors and operation costs.

- Increased Data Visibility: Keep critical information as accurate as possible in real-time as items move throughout your operation.

- Increased Time Savings: Eliminate the need to process each item individually when bulk quantities can be scanned at once.

- Increased Accuracy: Using RFID technology is the most accurate way to manage moving inventory. RFID technology improves barcode inventory systems and is worlds better than traditional manual/paper inventory methods.

- Reduced Costs: Knowing important inventory and shipping information helps you make cost-saving decisions and tailor orders.

Getting Started with RFID

Getting started with RFID requires a little bit more than buying a reader and slapping a tag on what you want to track. Our solutions are strategically designed for your warehouse’s requirements. As a result, we take the time to evaluate which combination of RFID tags, readers, antennas, printers, and software will work best for your specific application.

With over 20 years of experience working with our customers, we have seen many common challenges and mishaps when implementing RFID systems. When you work with RMS Omega, you work with a dedicated Account Manager who will be your point of contact from the start. We will support you from the initial project design and through the implementation, deployment, and ongoing maintenance, optimization, and analysis of your RFID system for years to come.