Complete RFID Technology Systems: Tags, Printers, Readers & Software

RFID technology is ideal for busy, high-volume operations that require automated, comprehensive data capture. However, getting started with RFID technology requires a little more leg work than more than buying a reader and slapping a tag on what you want to track. Our solutions are strategically designed for your requirements, meaning we take the time to evaluate which combination of RFID hardware, tags, and software will work best for your application.

Labels & Tags

RFID labels and tags serve as the building blocks of your system. Accurate RFID data collection hinges on the durability and readability of your labels, so preliminary tag testing is often necessary. RFID tags are either active or passive. Active tags are continuously broadcast to readers, while passive tags are only read when in the range of a reader. Beyond active and passive functionality, tags can also have different form factors.

- Adhesive Labels – have an embedded passive RFID tag, enabling tracking once the label is affixed to items. Adhesive labels are available in various sizes, label materials, and adhesive strengths for a variety of tracking applications.

- Specialty Labels – are designed to withstand extreme environments, RFID disruptors, or unique deployments. Our labeling experts can help you choose the right label based on your application, provide custom design and formatting, and even test it in your environment.

- Hard Tags – are durable, rigid, encased tags that withstand harsh environments and handling. RFID hard tags are built to be rugged and durable. They are designed to withstand exposure to elements like water, dust, chemicals, and temperature variations, making them suitable for outdoor and industrial applications.

Printers

RFID printers combine traditional printing capabilities with RFID encoding functionality, allowing users to print information on labels or tags while simultaneously encoding RFID data. By printing RFID labels in-house, organizations gain wider control over label customization and can lower printing costs over time. Alternatively, companies can leverage label pre-printing services.

There are several different printer types available depending on printing volume, form factor, and operating environment.

- Mobile Printers – for small-volume printing at the point of application.

- Desktop Printers – small-volume stationary printing.

- Industrial Printers – high-volume printing for demanding environments.

RFID Readers

Next to tags, RFID readers and scanners are the most important parts of the RFID system when it comes to collecting and relaying data. RFID scanners and readers are devices used to wirelessly identify and track tagged objects. Much like RFID tags, readers are also classified by which frequency they operate at, such as low-frequency (LF), high-frequency (HF), and ultra-high frequency (UHF).

An RFID system can incorporate fixed, mobile, or hybrid reading approaches. Either way, readers are essential for capturing the encoded data on tags.

- Mobile Readers – these portable readers can be carried around to scan tags in different locations. Mobile readers are often utilized to rapidly perform inventory audits, validate SKUs, and locate missing assets or products with a Geiger counter feature.

- Fixed Readers – these readers are fixed at strategic checkpoints like doors, conveyors, and warehouse racking. Fixed readers can be used to create zones for managing inventory movements, tracking assets, and monitoring work-in-process.

- Integrated Readers – as the name implies, these are readers that are integrated into other devices like dock door portals, kiosks, or mobile computers. They streamline tag reading and validate large volumes of tagged products at once.

- Antennas – while not technically readers, RFID antennas work in conjunction with scanners and tags to facilitate communication. Antennas create electromagnetic fields that power passive tags and enable a data exchange.

Software

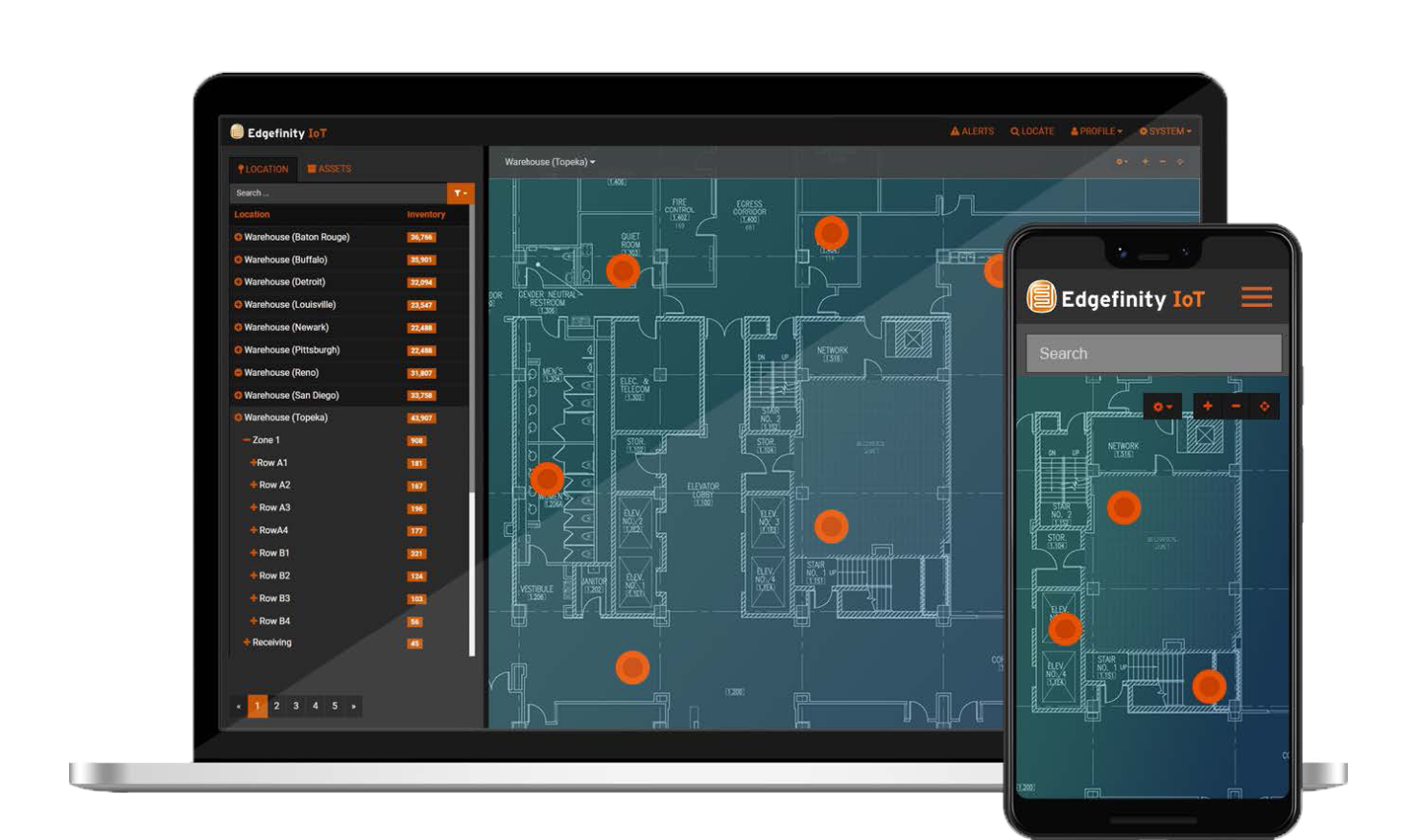

Software is the brains of your RFID infrastructure. Without it, the data that’s collected by your RFID hardware is almost useless. The information collected from your readers is viewed, managed, analyzed, and exchanged in advanced software. This closes the loop, enabling complete operational visibility. Our network of partners allows us to recommend software products that deliver the features you need and integrate seamlessly into your asset, work-in-process, and inventory-tracking workflows.

Asset tracking – Track important assets and equipment with RFID technology and view their location in your asset management platform. Use RFID to locate lost and missing assets and reduce excess spending on replacement equipment.

Inventory Management – Automate inventory counts and updates by strategically using RFID technology. Reduce excess ordering and overstock with a more accurate picture of real-time inventory levels, so you only order what you need.

Work In Process – Reduce lost materials, delayed product movements, and incorrectly pulled materials making their way out of the manufacturing facility using RFID.