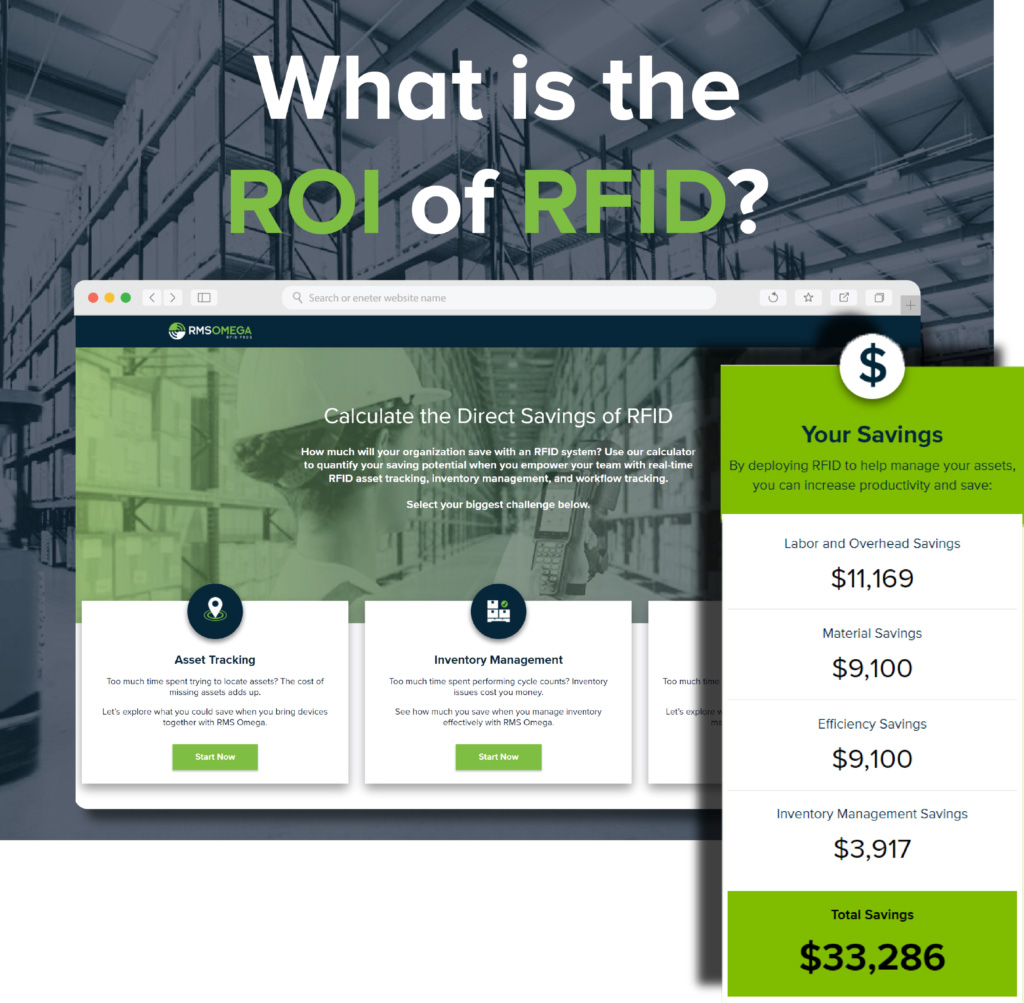

Access our exclusive savings calculator and enter basic information about your operations to receive an instant, detailed breakdown of potential savings across various categories. Ready to see the savings?

Calculate your RFID savings potential across three major use-cases.

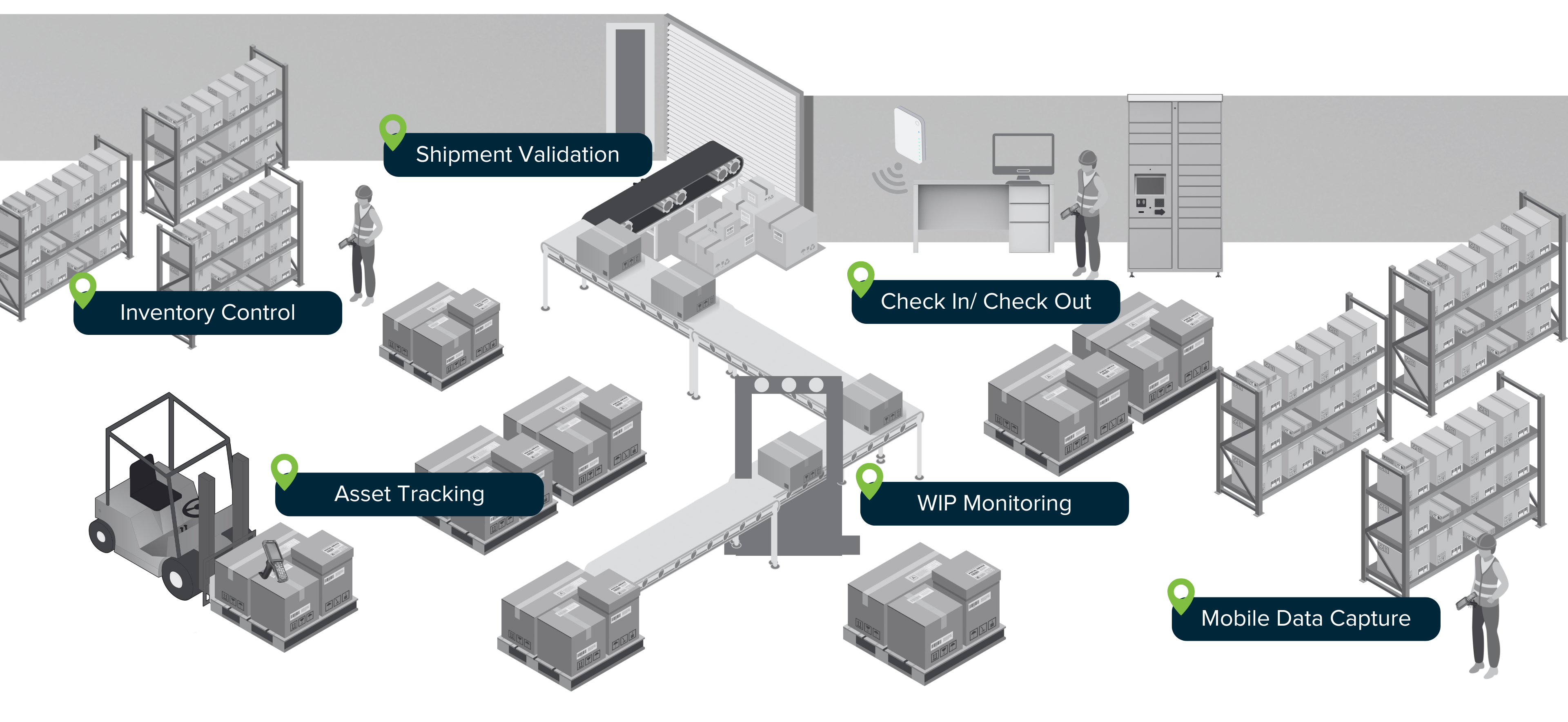

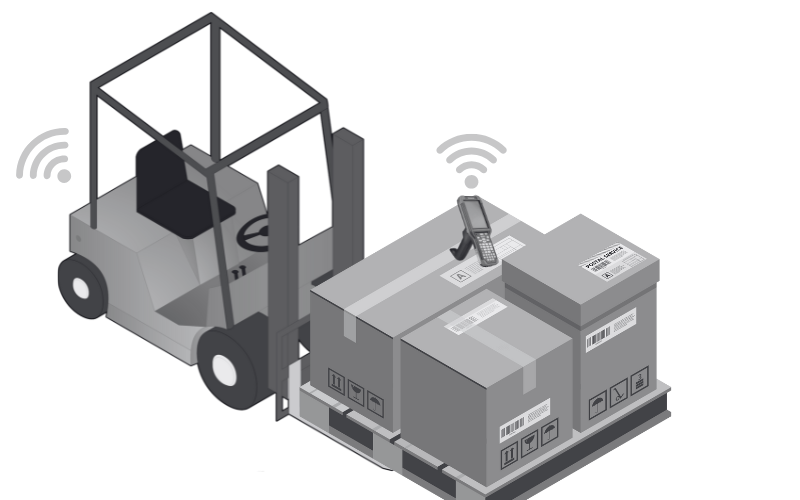

Asset Tracking – Monitor equipment usage and quickly locate lost or missing assets to reduce loss and enhance your production capabilities.

Inventory Management – Maintain accurate inventory records and track stock as it moves in, out, and around your facility. Using RFID for inventory management improves data accuracy and slashes the time and money spent on cycle counts and audits.

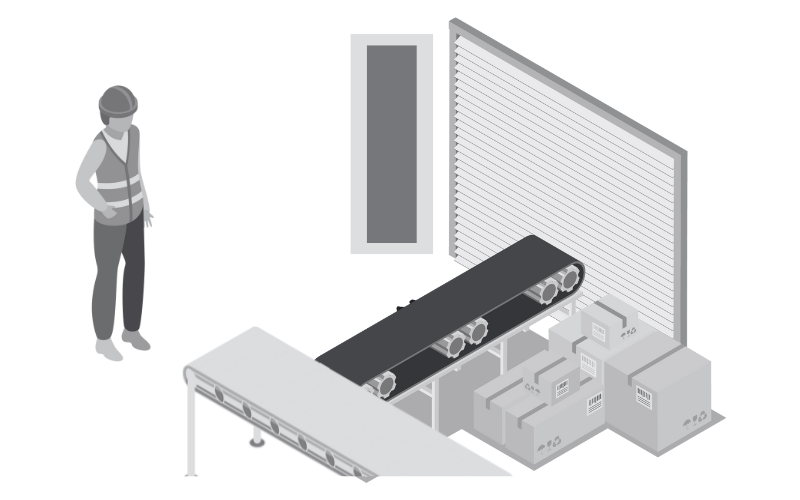

Workflow Tracking – Get a clear picture of your production operations to identify bottlenecks and track parts and materials throughout their lifecycle. Track critical components as they enter your plant, proceed through a workflow and ship out to a new location.

Calculate Savings