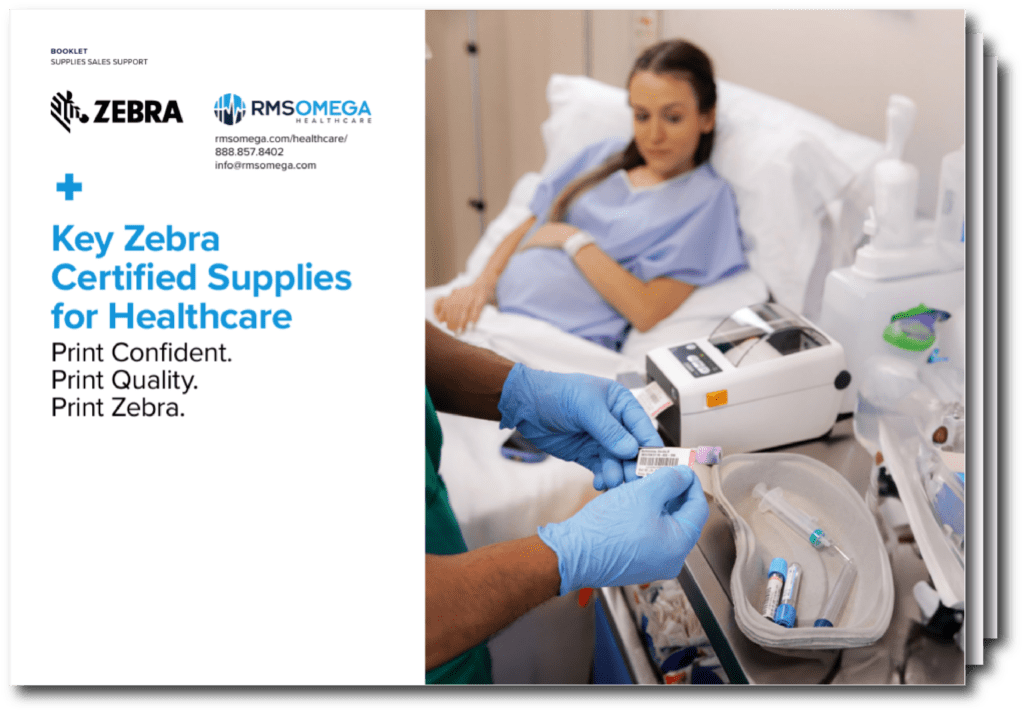

Healthcare Labels and Wristbands For Accurate Data Collection

Healthcare labels must meet the strict demands of medical environments, where accuracy, durability, and compliance are critical. That’s why RMS Omega provides a full range of healthcare labeling solutions. Most commonly, we support healthcare labeling applications such as patient ID, specimen tracking, blood bag and IV labeling, cryogenic storage, autoclaving, and more. Our labels withstand extreme temperatures, humidity, chemicals, and sterilization, delivering lasting performance and accurate data capture across all care settings.

Healthcare Labeling Applications & Use Cases

The right label clearly and reliably communicates information to support patient safety and regulatory compliance. We specialize in offering labels and integrated data capture solutions across these common healthcare areas.

- Positive Patient ID – Wristbands are designed for both patient comfort and usability. This enables clinicians to obtain an array of patient data from a single scan.

- Specimen Tracking – Laboratories rely on labels that can withstand moisture, chemicals, and temperature extremes to maintain sample integrity and accurate testing results. Barcode labels ensure proper chain-of-custody and help reduce manual data entry.

- Blood Bag & IV Labels –Specialized labels designed for blood banks and IV lines must meet strict regulatory standards and stay legible despite exposure to refrigeration, handling, and moisture.

- Cryogenic & Cold Storage – Cold storage and cryogenics require durable polyolefin labels that can withstand extreme temperature conditions.

- Autoclaving – Healthcare professionals sterilize surgical instruments, and their asset labels, at high temperatures. Autoclave-resistant labels must remain intact and legible to ensure compliance with infection control protocols.

- Asset & Equipment Tracking – Labels on medical devices, beds, wheelchairs, and other hospital assets help improve inventory management and reduce loss or misplacement, especially when integrated with RFID or barcode scanning technology.