Track Important Tools, Assets & Equipment with RFID

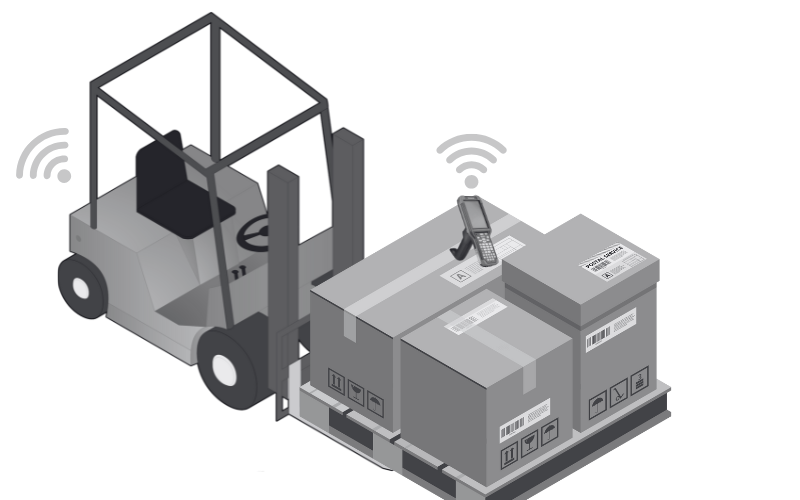

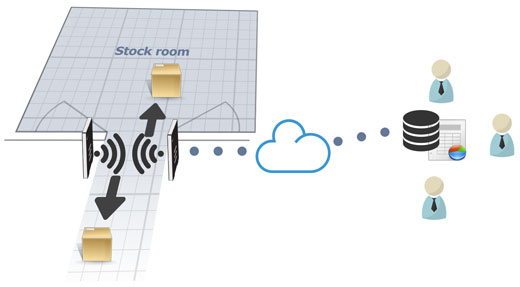

RFID check-in/check-out systems allow enterprises to monitor the usage of equipment, parts and materials, and inventory. By incorporating passive RFID tags and fixed readers, checkpoints can be made for key items at bins, warehouse bays, and even dock doors. As a result, organizations gain visibility into the utilization of their assets and can create an automated chain of custody. More importantly, these systems eliminate loss, replacement expenses, and overall lack of visibility.

Check-in/ Check-out systems are ideal for any organization looking to monitor the use and consumption of assets and inventory. Common monitoring applications include:

Check-in/ Check-out systems are ideal for any organization looking to monitor the use and consumption of assets and inventory. Common monitoring applications include:

- Shared equipment & IT.

- Personnel in a facility.

- Parts and equipment that go to a job site.

- Inbound & outbound inventory.

- Marking inventory in and out of stock.

Benefits of an RFID Check-in/Check-Out

Keep track of the tools, equipment, and assets your team needs. RFID check-in/check-out creates a documented log of assets taken out of stock or off-premise and automatically updates inventory in addition to generating real-time alerts to users.

RFID check-in/check-out solutions bring many advantages to warehouse and manufacturing operations, including:

- Automated equipment check-in/check-out processes.

- Accurate inventory checkpoints at dock doors, bins, and bays.

- Automatically update any database with asset location.

- Monitor unauthorized usage and track down lost items.