Reduce Delays by 80% and Optimize Your Enterprise with Zebra MotionWorks

MotionWorks Location Solutions enables enterprises with complete visibility of critical assets, people, and goods through real-time data. With this in mind, organizations can gather quantifiable data that surrounds the critical aspects of their daily operations. Since it is powered by the Zebra Savannah location engine, MotionWorks can generate actionable insights that streamline workflows, boost efficiency, lower operating costs, reduce delays, and improve the utilization of assets.

In fact, MotionWorks has helped organizations reduce delays caused by missing equipment by 80% and improve equipment utilization by 20%. Above all, MotionWorks is used globally by aerospace, automotive, retail, logistics, and manufacturing organizations to drive smarter business decisions. Altogether this intelligent edge solution leverages real-time location technology to provide the following benefits:

- Increased visibility and control across the enterprise

- Information on the location and condition of critical assets

- Automated tracking of finished goods and materials used in production

- Actionable insights that help you reduce waste and optimize

- Improved workflows for plant operations

- Faster turnaround times for customers

- The ability to enforce safety and compliance measures

Take All Areas of Your Organization to New Heights

Zebra MotionWorks utilizes location technology for asset, material, yard, and warehouse management. As a result, MotionWorks brings added visibility, insight, and opportunities for optimization across all areas of the enterprise.

MotionWorks Asset

In addition to tracking critical people and items, MotionWorks Asset provides valuable data about the health and status of assets. Because organizations know the precise status and location of assets, they can make dynamic routing decisions that optimize their distribution. MotionWorks Asset can also be used to track vehicles, tools, and equipment, helping enterprises execute better delivery services and more efficient production. In addition to having up-to-the-second data, MotionWorks Asset provides:

- Reduced cost of physical asset loss

- Increased productivity through reducing manual processes

- Automated visibility to improve workflows

- Decreased downtime

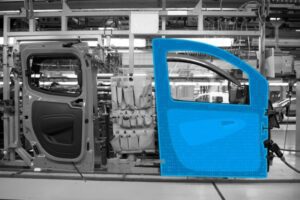

MotionWorks Material

With MotionWorks Material, supply chains run smoother than ever. Due to real-time location data, this solution automates material flows and initiates replenishment triggers while integrating with ERP. The solution also provides real-time information about the plant floor and compares performance against historical data. In turn, supervisors can confidently manage their output and shift resources where they are needed. Furthermore, businesses can ensure reliable and consistent deliveries for their customers. By optimizing logistics with MotionWorks Material organizations can:

- Avoid part shortages and supply chain disruptions

- Reduce costs from excess inventory

- Eliminate wasted time and materials

- Execute just-in-time delivery

MotionWorks Yard

Yard management consists of keeping on top of a continuous flow of vehicles, materials, goods, schedules, and equipment. Consequently, organizations need an intelligent application like MotionWorks Yard that manages it all in real-time. With insights and prescriptive analytics from MotionWorks, yard managers can optimize space and turnaround times, increase throughput, and lower costs. This allows yard managers to synchronize staff, systems, and shipments while optimizing their overall operations. Other benefits of MotionWorks Yard include:

- Automated trailer movements through real-time data

- Maximized throughput and gate transactions without increasing space

- Lower operation, fuel, and maintenance costs

MotionWorks Warehouse

MotionWorks Warehouse tracks large volumes of goods and assets within the four walls. More importantly, it tracks operations in real-time and integrates with existing WMS. As a result, warehouse managers can draw upon intelligent insights in order to streamline their processes while increasing worker productivity and order fulfillment. Furthermore, Zebra’s intelligent warehouse solution automates manual processes and eliminates loss of goods or mis-shipments that can result from human error. Ultimately, MotionWorks Warehouse helps businesses:

- Improve labor performance with directed workflows

- Create audit trails for security and quality control

- Strengthen process over time with operational intelligence

- Improved shipping accuracy

- Increased finished goods tracking and workflow efficiencies

Download the MotionWorks Brochure

Working with a Certified Zebra Solutions Partner

Ultimately, it is critical to have a partner who understands how to implement this technology so it yields the best results for your business and maximizes your investment. Regardless of your industry or application, RMS Omega leverages years of expertise and a premier partnership with Zebra to design solutions that solve your specific pain-points. With RMS Omega you will work with a team of certified Zebra solutions experts who will take the time to understand your organization’s challenges and offer continued guidance and assistance through solution design, implementation, training, and ongoing support after deployment.