RFID and RTLS Solutions For The Automotive Parts Tracking

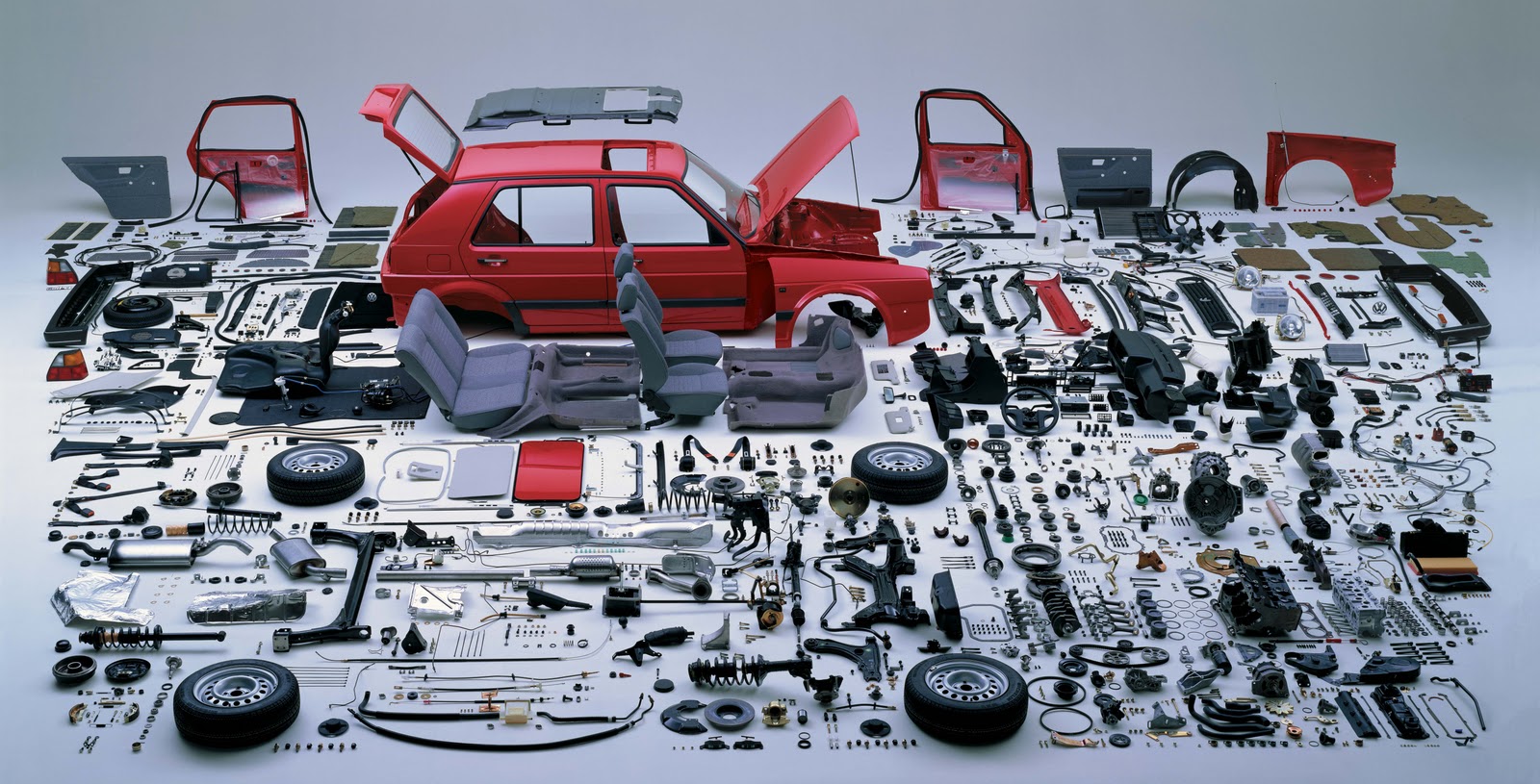

With the average vehicle having around 30,000 parts, automotive suppliers need efficient workflows and complete visibility over the products and materials moving through their supply chain. RFID technology is the best way to streamline data collection and increase the value of the data collected. An RFID solution uses the latest hardware and software to increase visibility over:

- Vehicle parts/trolley tracking

- Outbound & inbound inventory

- E-Kanban production

- Work in process

- Tools and equipment

- Final assembly and staging

Working with premier hardware and software partners, RMS Omega Technologies has helped companies like Mercedes-Benz and Bridgestone to ditch manual inventory processes and achieve enterprise-wide, real-time product visibility.

Creating An Automated, Optimized, & Efficient Automotive Supply Chain

Automotive suppliers undoubtedly face a demanding, fast-paced industry and can’t afford to be plagued by errors and inaccuracies. For this reason, it is our mission to craft solutions with RFID and RTLS technology that help suppliers achieve greater visibility over critical operations so they can become more accurate and efficient.

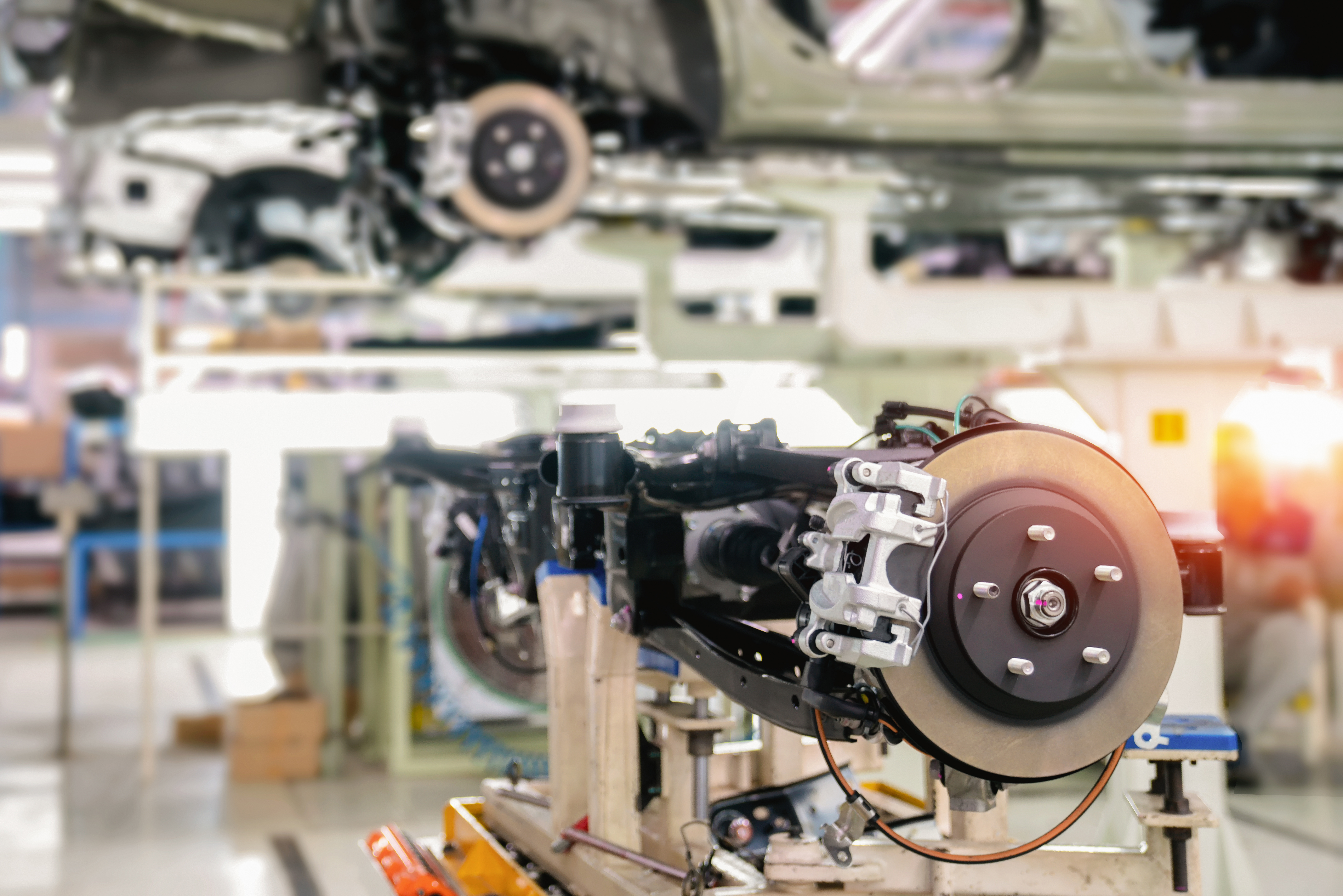

Asset Tracking

Receive location data for critical parts, materials, and equipment needed for your operations. Eliminate the downtime that comes with searching for missing assets with the last known locations and real-time tracking.

Inventory Management

Accurately manage, replenish, and monitor stock levels with automatic inventory counts and inventory level notifications. Get precise visibility over part numbers, quantities, and their locations throughout your warehouse or manufacturing facility.

Process & Workflow Automation

Save time and labor by automating workflows. Automating manual tasks helps organizations eliminate errors and achieve operations that are leaner, cost-effective, and optimized.

Work in Process

Get real-time location data on parts and materials as they progress through manufacturing processes and assembly. Track parts and products as they progress through each stage and become a finished good.