Find Missing Items with RFID Asset Tracking Software

Misplaced assets and equipment result in costly delays in operations, along with plenty of unneeded frustration. Asset tracking systems and RFID asset tracking software help organizations avoid these pitfalls. With RFID tags, leading RFID readers and hardware, and asset tracking software, organizations can quickly locate valued assets, saving on accrued costs from potential delays.

![]()

Benefits of RFID Asset Tracking Software

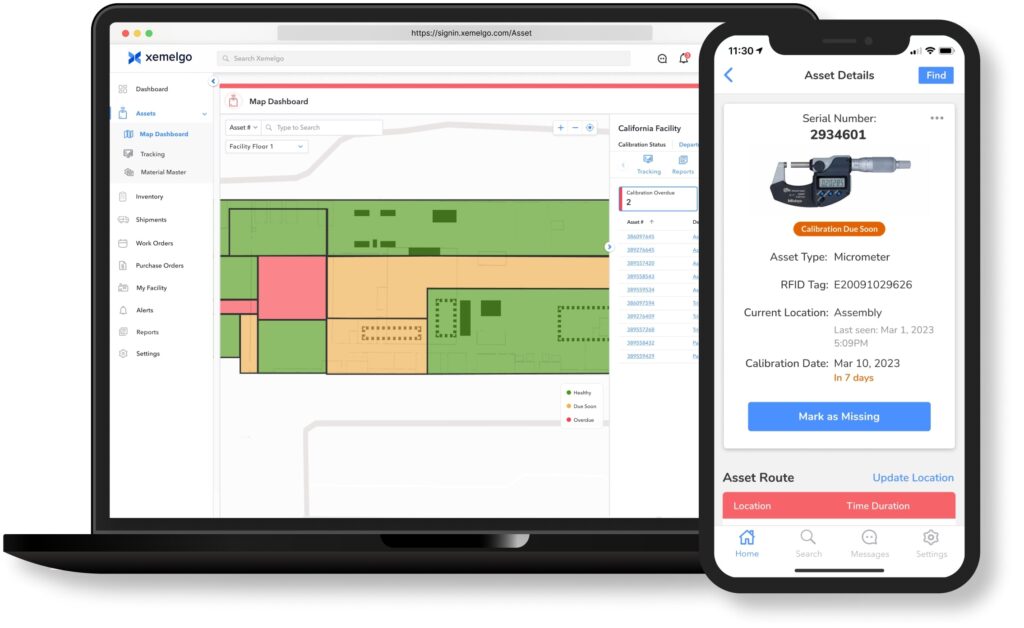

By combining RFID technology with intelligent software, you can create a complete system for collecting real-time data on the location and movements of critical assets around your facility. Since RFID does not require a direct line of sight, it allows you to find “missing” assets that would have previously been written off as lost with a barcode system. Working in conjunction with RFID readers, asset tracking software provides these key features for asset management.

- Report missing assets with instant notifications.

- Defined zones within a facility for each asset.

- Intelligent alerts for asset maintenance, calibration, expiration, etc.

- Visual floor plans and asset mapping.

- Instant audits & floorplans.

- Real-time asset tracking & locations.

Building A Complete Asset Tracking Solution

RFID asset tracking solutions help organizations increase asset visibility, erase lead time, minimize losses, and automate important processes. While asset tracking software will serve as the brain and central dashboard for your system, you will need some additional components for collecting, aggregating, and feeding data to your software.

RFID Asset Tags – tested tags for your exact asset type and environmental challenges.

Handheld Readers – gun-style mobile readers for tracking down missing item(s).

Fixed Readers – create checkpoints and zones that prompt the software to trigger notifications on asset movements.

Antennas – link your fixed reader data to your software.

Printers – encode your own RFID labels in-house and print on demand.

Implementing Asset Tracking Software

Getting started with RFID requires a little bit more than buying a reader and slapping a tag on what you want to track. Our solutions are strategically designed for your warehouse’s requirements. As a result, we take the time to evaluate which combination of RFID tags, readers, antennas, printers, and software will work best for your specific application.

Most asset-tracking solutions start with an onsite visit. This allows our experienced team to get a better idea of your facility’s unique layout, challenges, and processes. From there, our team will outline a technology recommendation and scope of work. Ultimately, our goal is to provide customers with a complete asset-tracking solution that makes operations more accurate and transparent. When you work with RMS Omega, we will be your one-stop for industry-leading RFID hardware, software, tags, service, and knowledge.