Automate Dock Door Inventory with Integrated RFID Portals

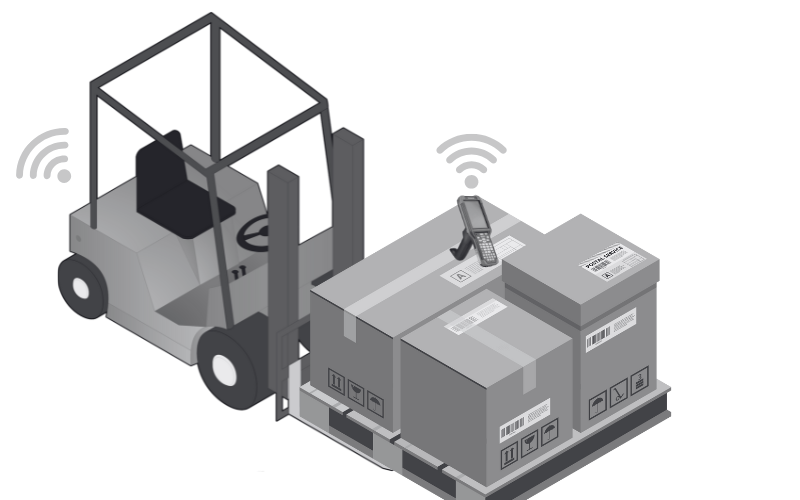

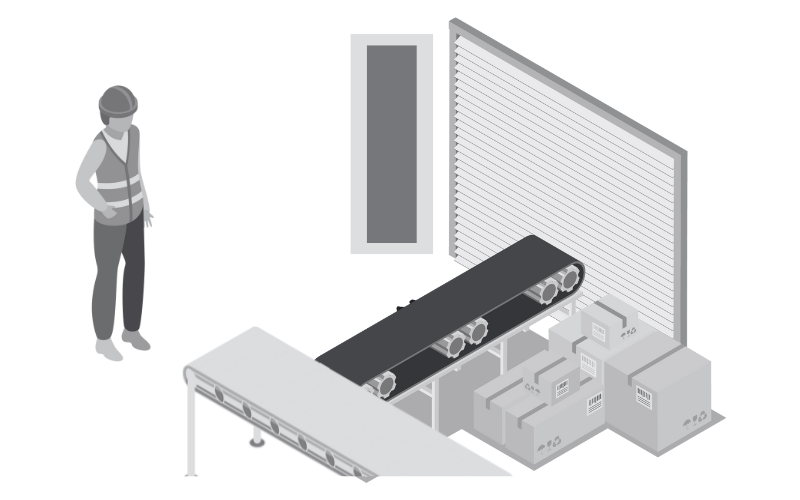

Warehouses face the pressing challenge of maintaining inventory accuracy as the volume of goods moving through facilities rapidly increases. Integrated RFID portals can automate inventory counts as items pass through dock doors, conveyors, zones, and more.

RFID portals and checkpoints enable enterprises to automatically update their WMS and inventory management systems through fixed, passive RFID solutions. In turn, businesses can obtain more accurate and automated processes for tracking inventory, assets, and workflows.

Integrated RFID Portal Features

Integrated RFID checkpoints save time and operating costs for inventory, WIP, asset tracking, and workflows. Therefore, by using RFID technology, organizations can obtain greater visibility over inventory moving in, out, and throughout facilities. Other features of this easy-to-implement, passive RFID solution include:

- Complete assembly and easy deployment.

- Full product support.

- Proven efficiency and visibility.

- Improving read accuracy for error reduction.

- Durable design to withstand challenging supply chain and manufacturing environments.